Beef processor increases spec accuracy by 30%

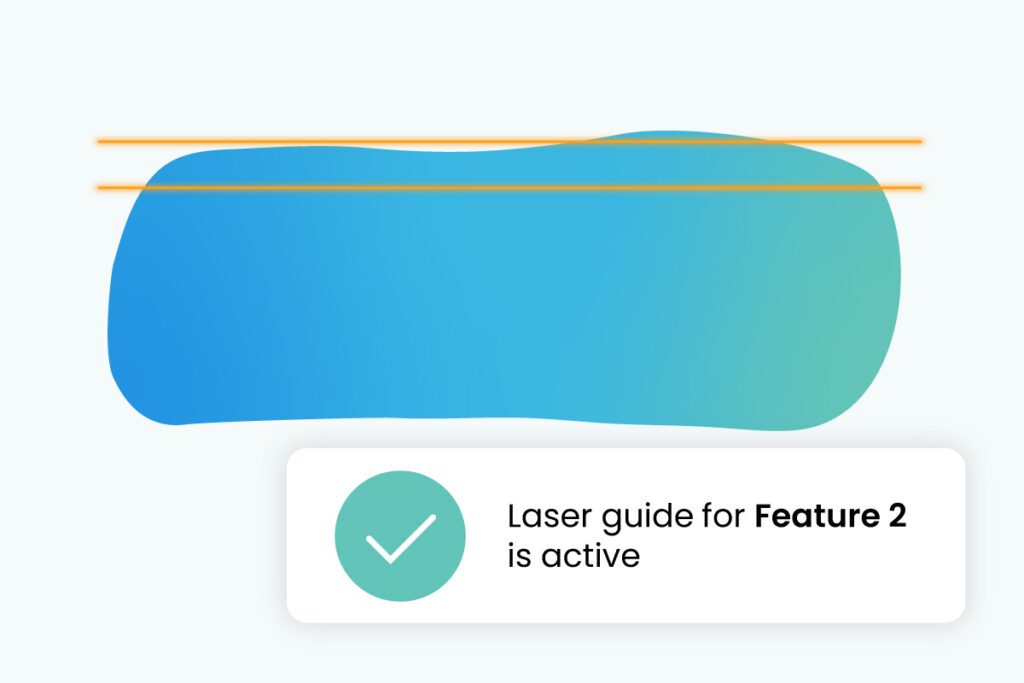

Laser Guidance

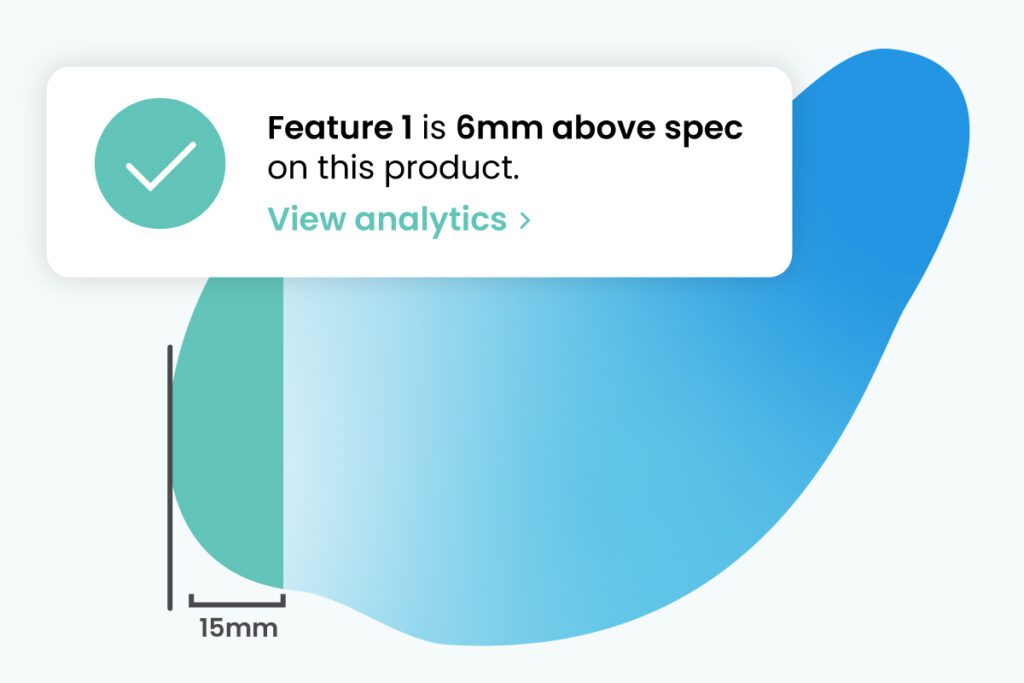

Specification Measurement

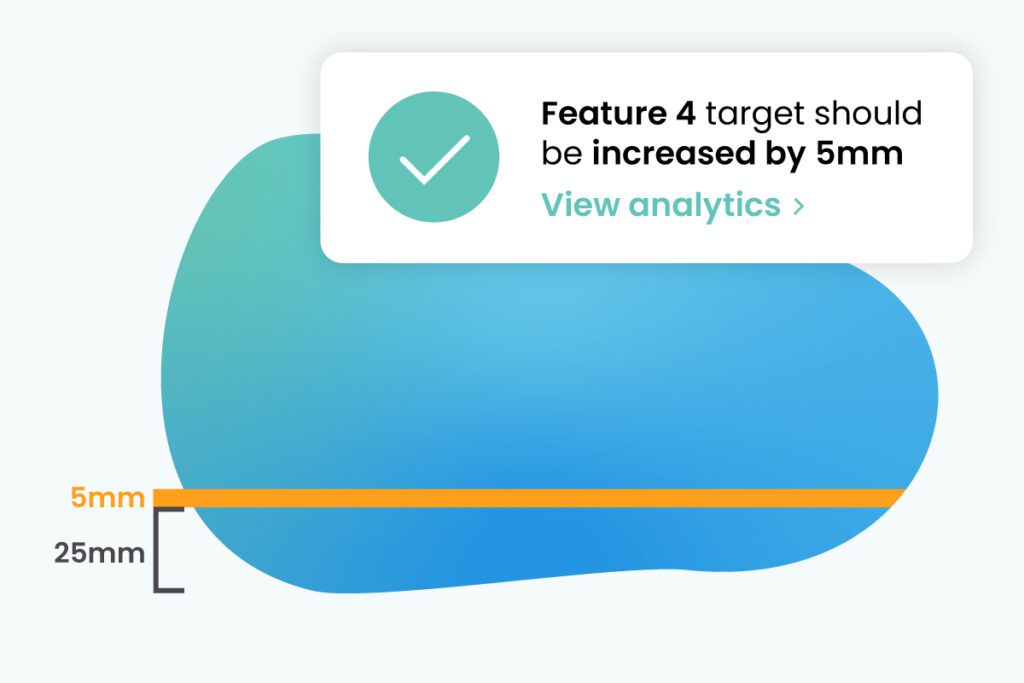

Specification Optimization

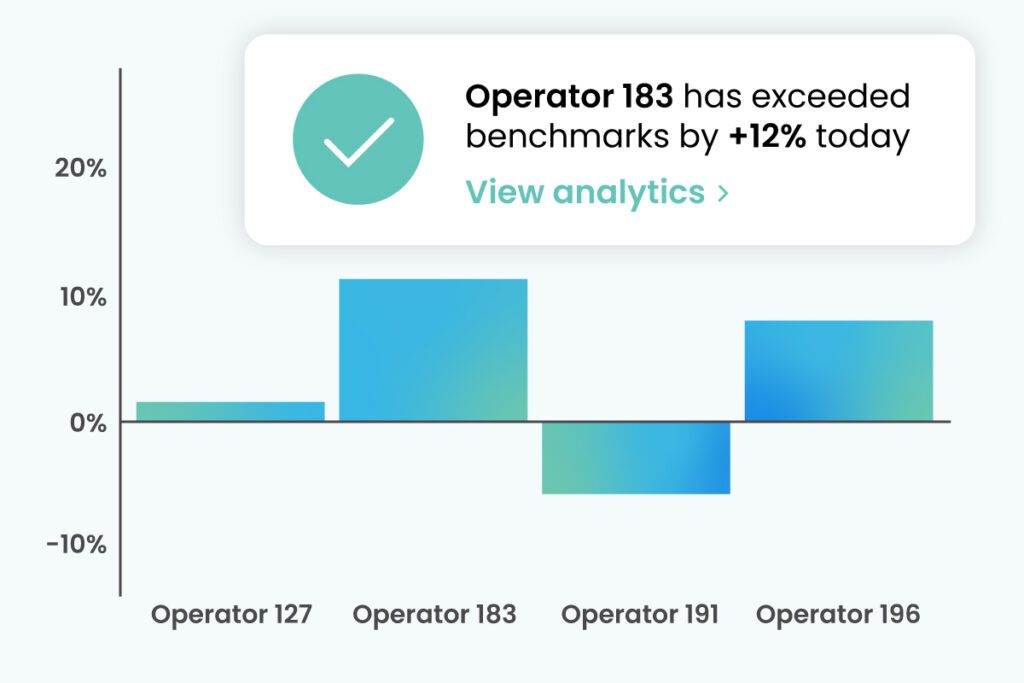

Staff Skills Analysis

Operator Feedback

$68,400

3,420 KG

LEARN MORE

$68,400

identified loss over 12 months

3,420 KG

yield increase over 12 months

Challenge

A leading beef production plant processes 300 head per day, with a variety of customer specifications for each feature and cut. On their most profitable cut, striploin primals, the backstrap refers to a piece of gristle on the length of the fat side that is removed for customer quality. Backstrap removal had a spec of 25mm (1 inch) for all customers, with the exception of one customer that required a 10mm (.4 inch) backstrap.

With their previous method, butchers measured backstraps by eye; under the perception that the 10mm spec was too small compared to the other specs, they consistently trimmed more than necessary. Supervisors very rarely screened for accuracy, and deviations from the 10mm spec were not immediately apparent. This manual approach resulted in the 10mm customer spec being overtrimmed by 12mm on average, while the 25mm backstraps were typically trimmed within 2mm of the spec.

Solution

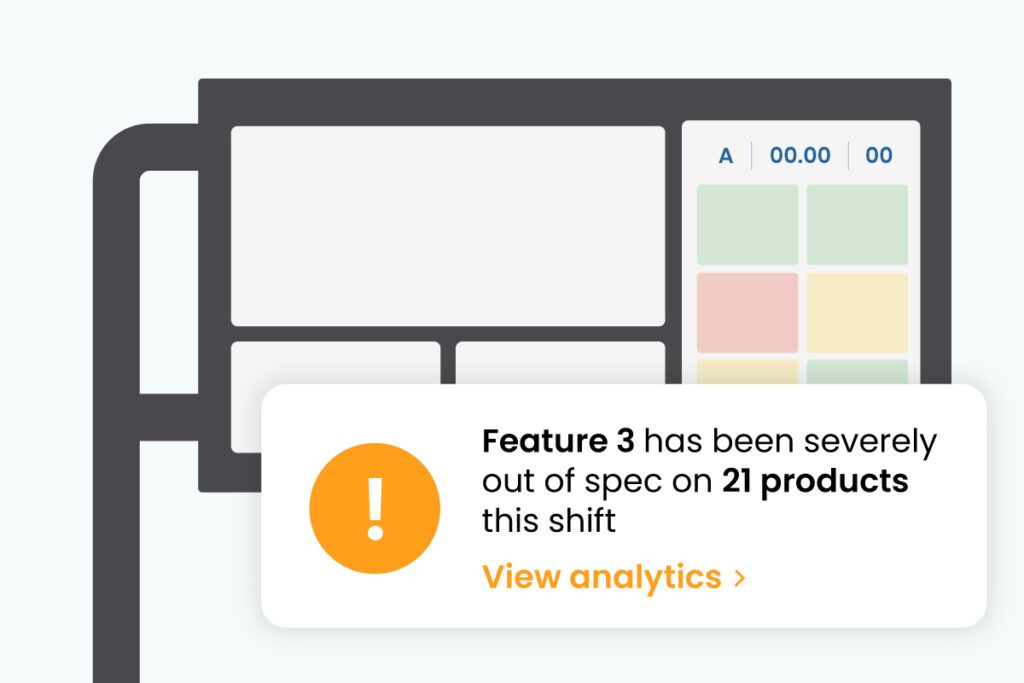

To address this quality issue, the beef processor implemented the FloVision Pro, which features laser trimming guides for butchers, sensors that measure primal features, and a manager dashboard with data and trend analytics.

The butchers used the FloVision Pro laser guides to accurately measure and trim the backstrap customer spec for every primal. Floor supervisors confirmed that butchers utilized laser guides, eliminating the perceived need for overtrimming. Company management reviewed the data, with a specific focus on trends in the 10mm backstraps. The FloVision Pro provided real-time and daily feedback on the primals and identified clear trends that went unnoticed without systematic measurement and monitoring.

Results

"The FloVision Pro system brought unapologetic, honest data and feedback loops. When you have a FloVision Pro, it's obvious what is wrong and what is right. That really unlocks a lot of control and value on the boning hall floor."

OPERATIONS MANAGER