AI for Food Production

Yield Optimization | Quality Control | Staff Skills

9,749,428 kg of food processed by our systems

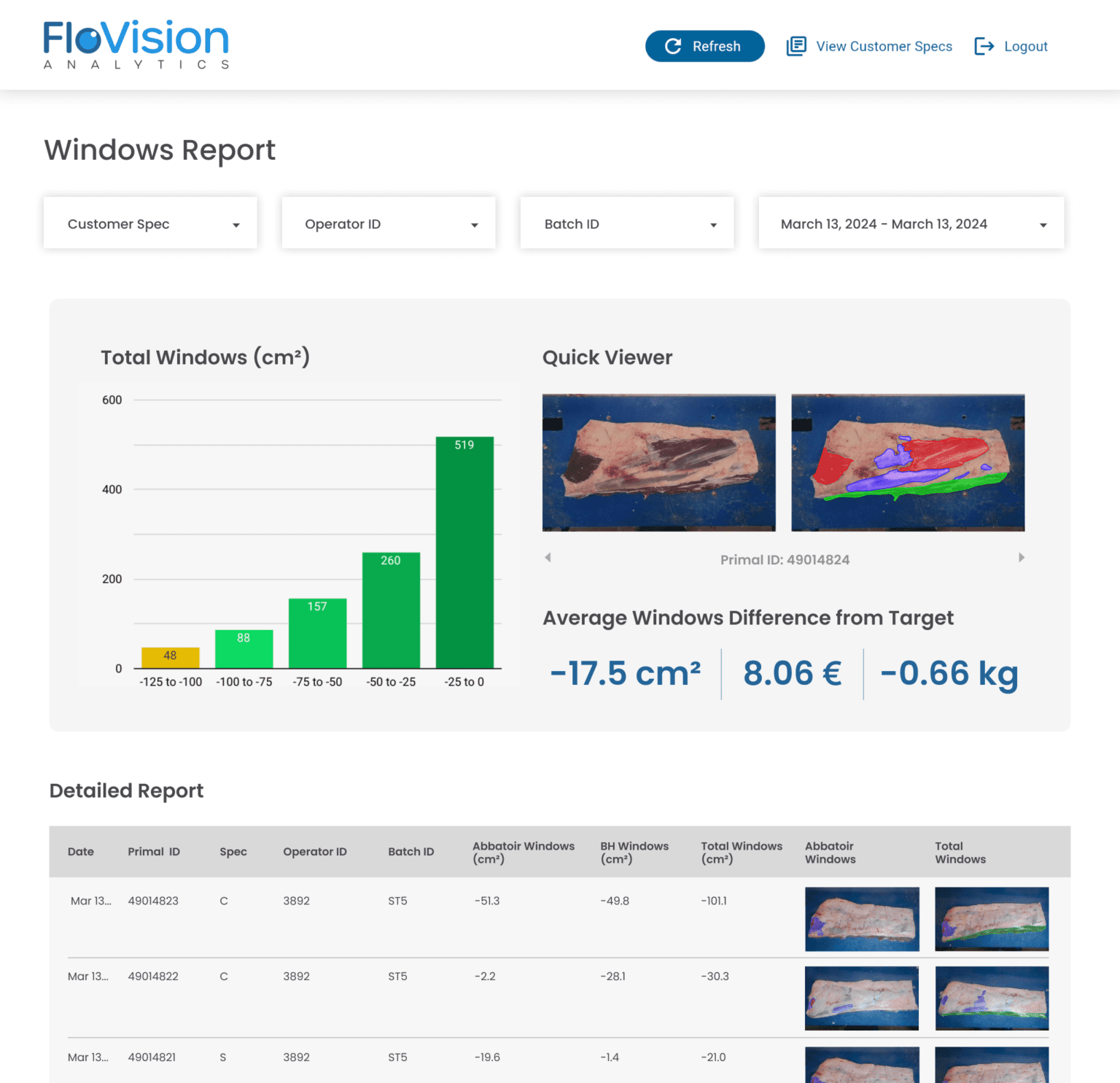

Yield Optimization

increased yield

0

%

Quality Control

product visibility & assessment

1

%

Staff Skills

reduction in staff training time

1

%

Modular solutions to measure, optimize, and control food production

Automated systems fit into any production line to measure product quality, customer spec, and staff performance. Identify gain and loss trends with comprehensive product, staff, and financial reports on the FloVision Analytics dashboard.

FloVision Nano

FOR Conveyor Systems

Understand food performance by measuring the most important features, unlocking yield and QA analysis, KPI reporting, and benchmarking of site operations.

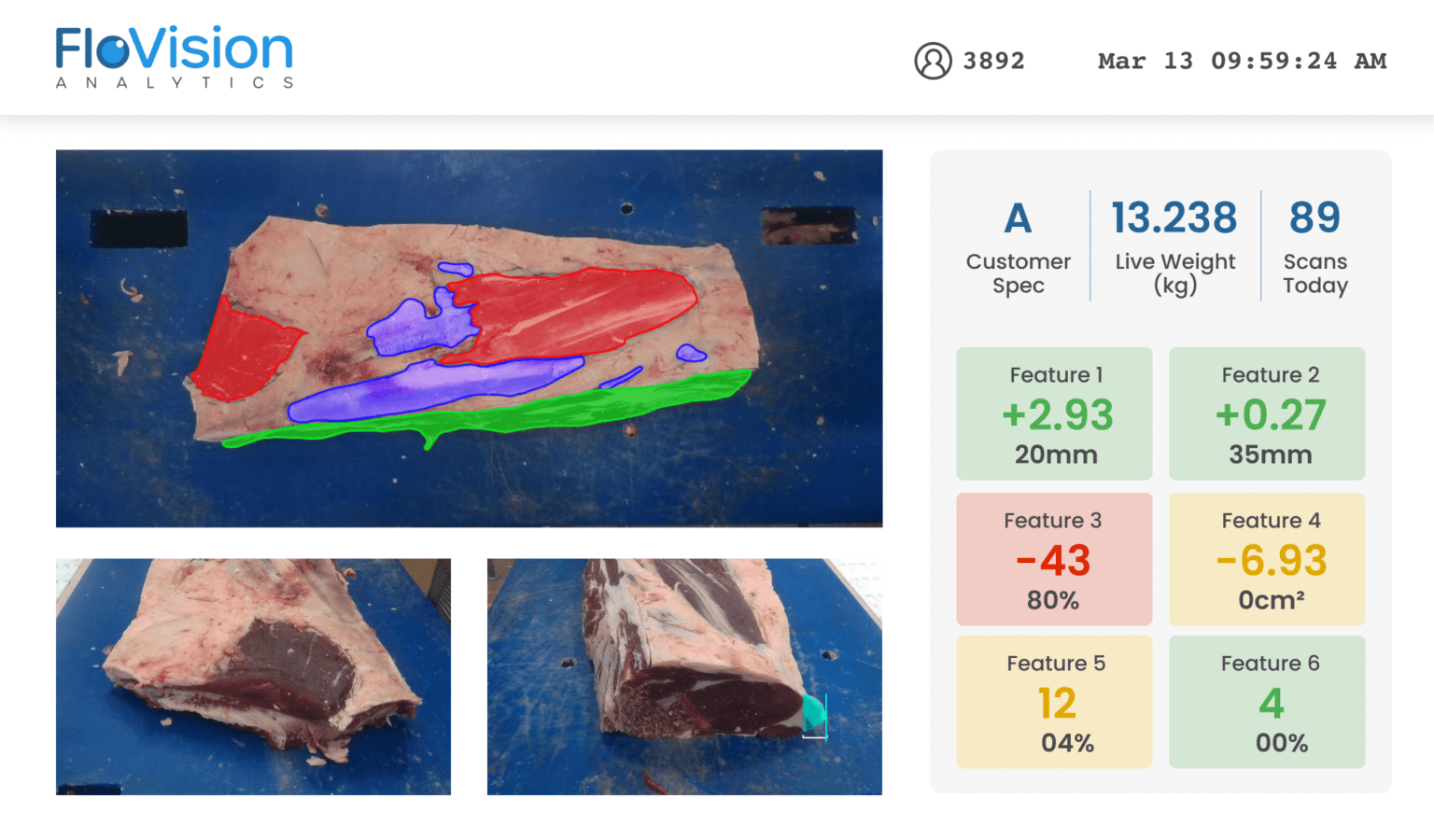

FloVision Pro

FOR PROCESSING STATIONS

Unlock real-time control and feedback loops, measuring all features while providing operator guidance and giving managers in-depth yield, quality, and staff skills analytics.

“FloVision Solutions has unlocked a huge value per head.

We can now see the variability of our processes and have the data to identify where we need to improve, how to train staff more effectively, and how to increase our yield.”

OPERATIONS MANAGER, BEEF PROCESSOR