Modular AI station to improve yield, quality, and staff skills

Unlock real-time control and feedback loops, measuring all features while providing operator guidance and giving managers in-depth yield, quality, and staff skills analytics.

Yield

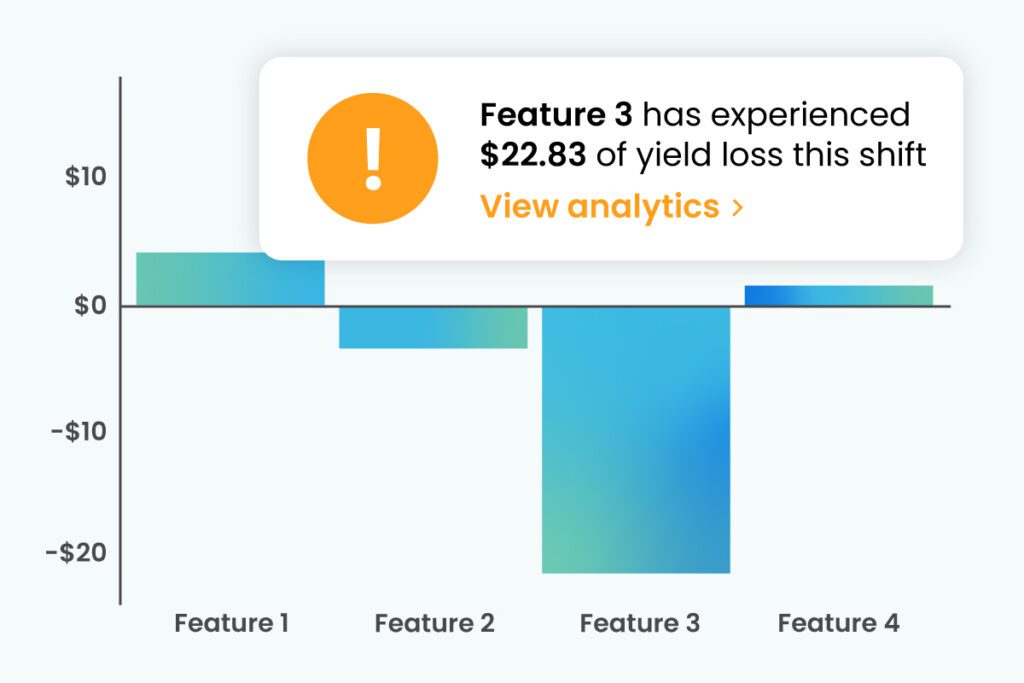

Identify yield gain and loss trends for every product feature with batch, staff, and financial performance reports.

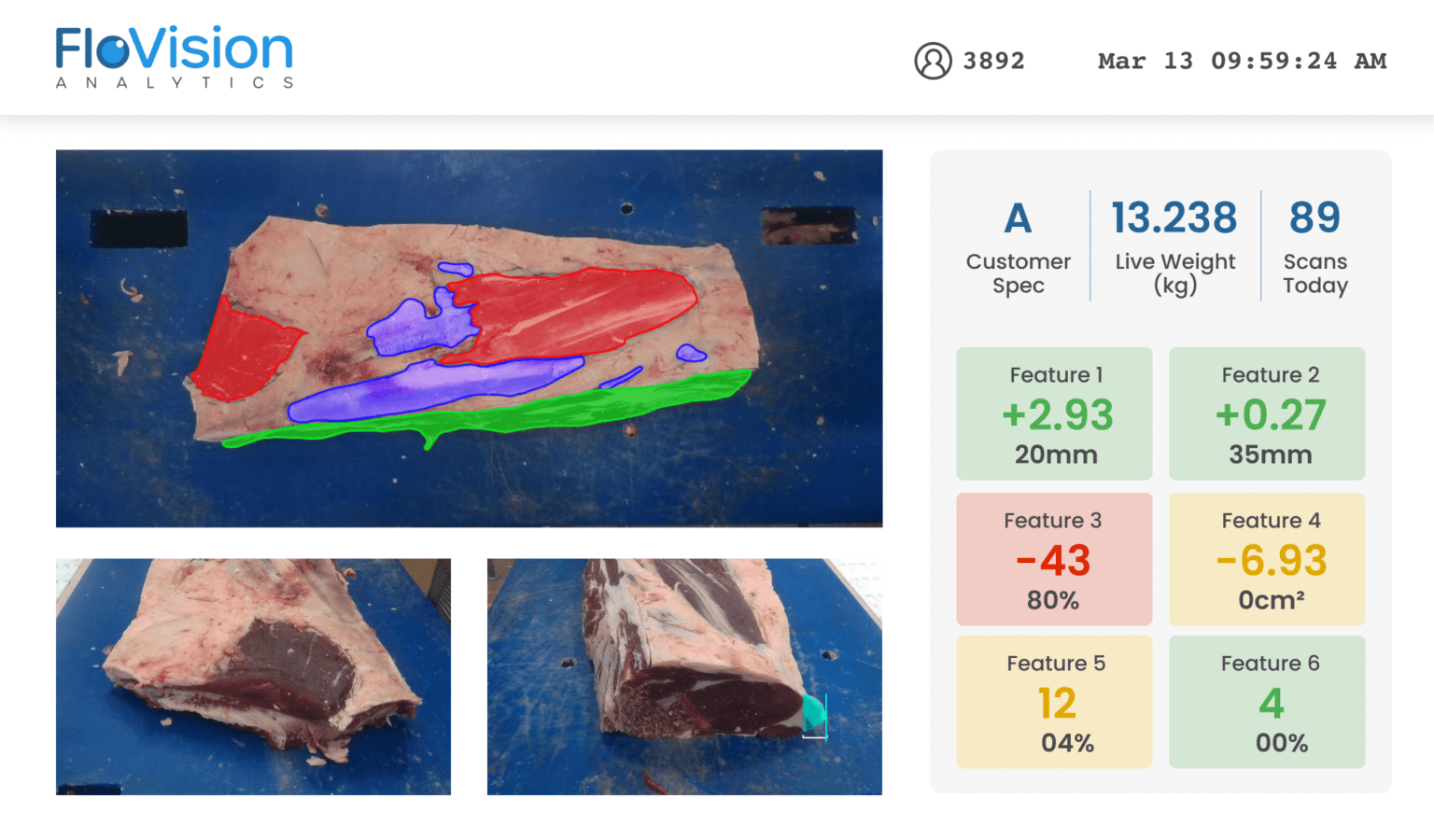

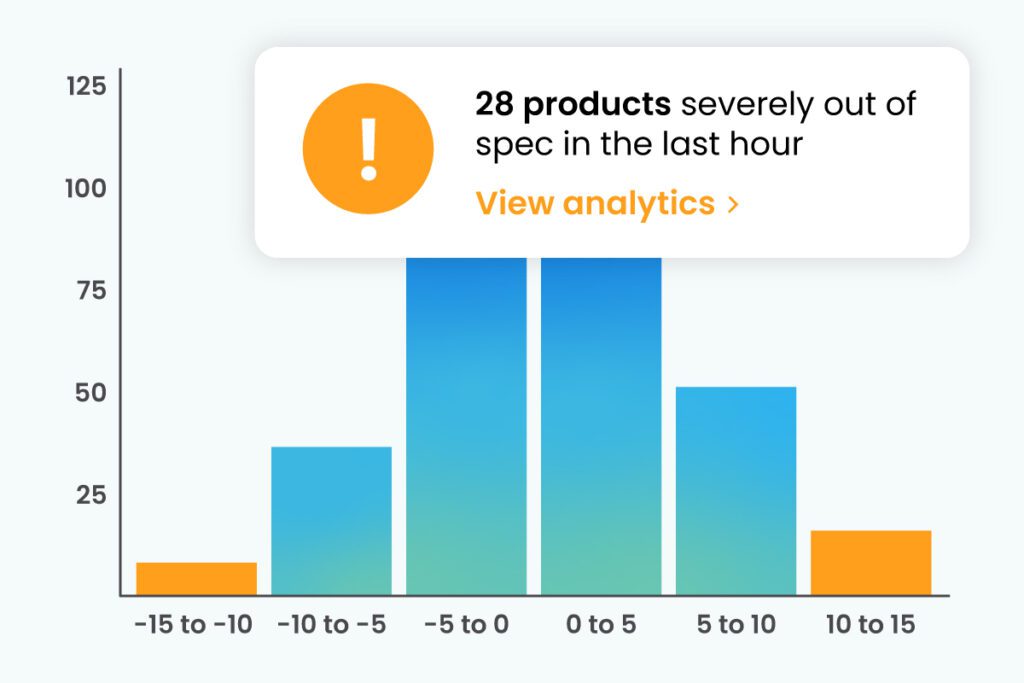

QA

Ensure targets are met using real-time guidance. Grade and classify food products, identify defects and errors, and automatically sort, regrade, or reject products.

STAFF SKILLS

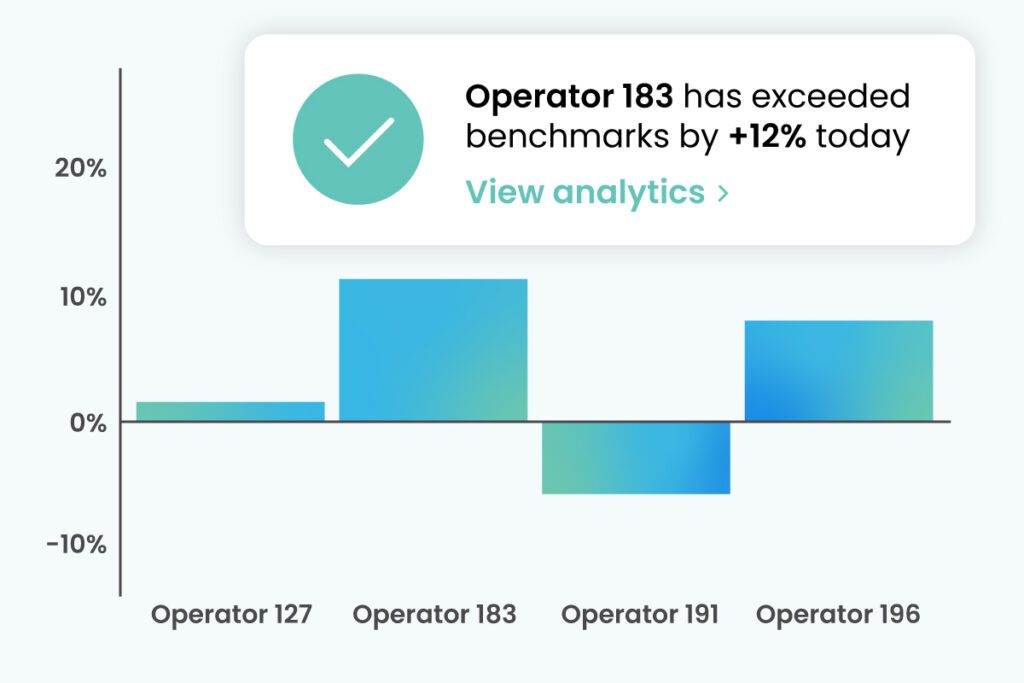

Halve onboarding time and provide individualized, focused staff training based on performance metrics

Modular

Customize the FloVision Pro station to identify, measure, guide, and control the highest priority features or production steps.

Production Manager, Beef processor

Yield Analysis

QA Analysis

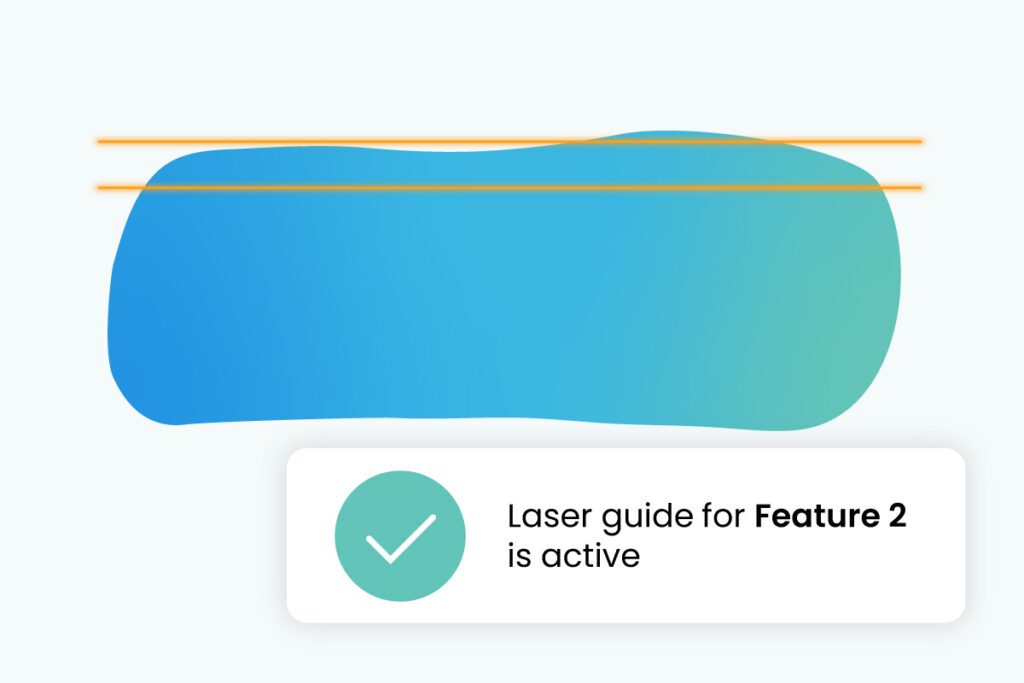

Laser Guidance

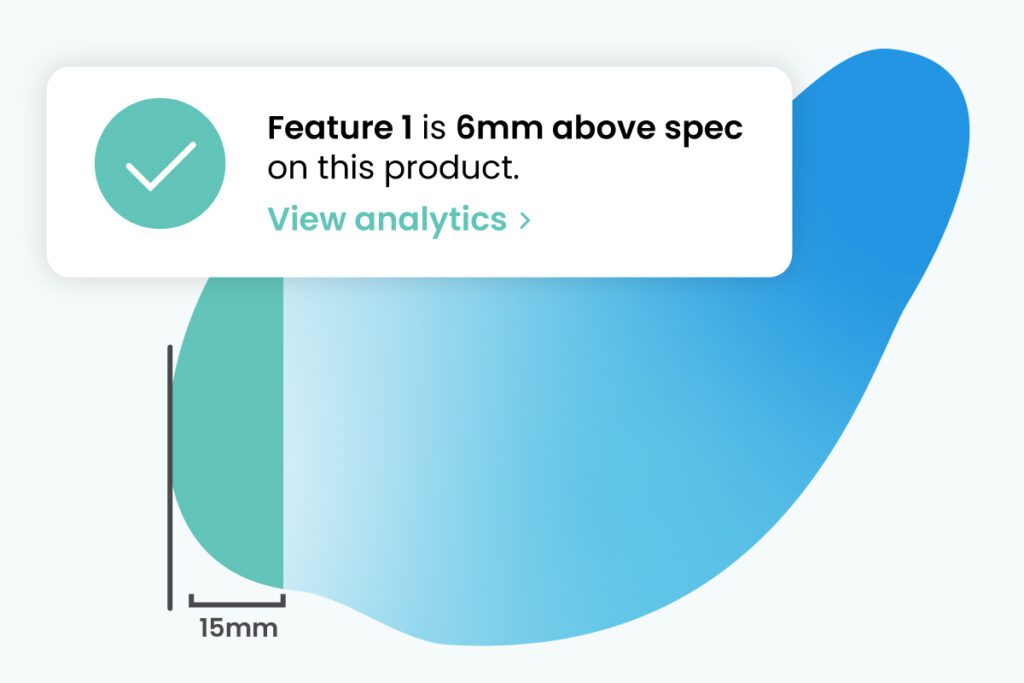

Specification Measurement

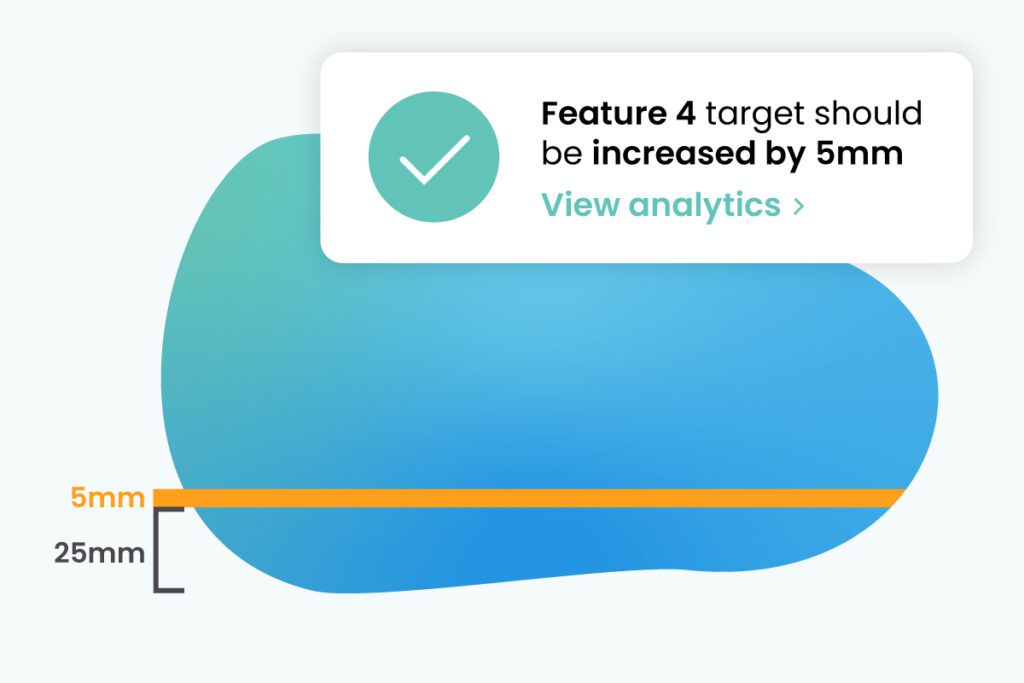

Specification Optimization

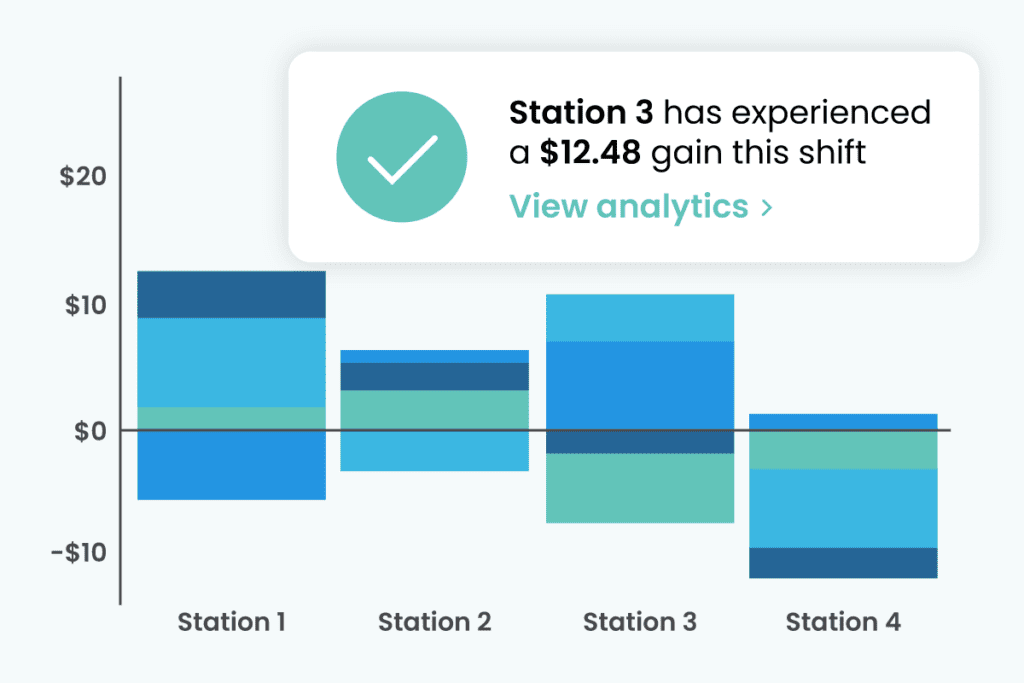

Financial Analysis

Staff Skills Analysis

Operator Feedback

Grading & Classification

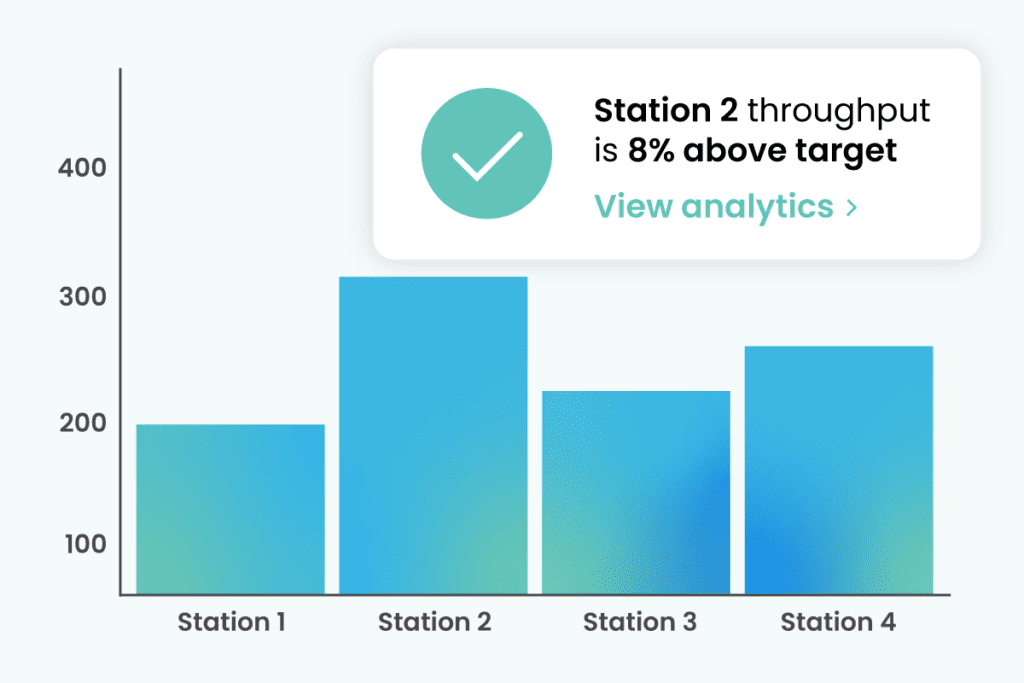

Productivity Analysis

Load Cell

Defect Detection

Supervisor Alerts

Label Reading

Traceability

Foreign Body

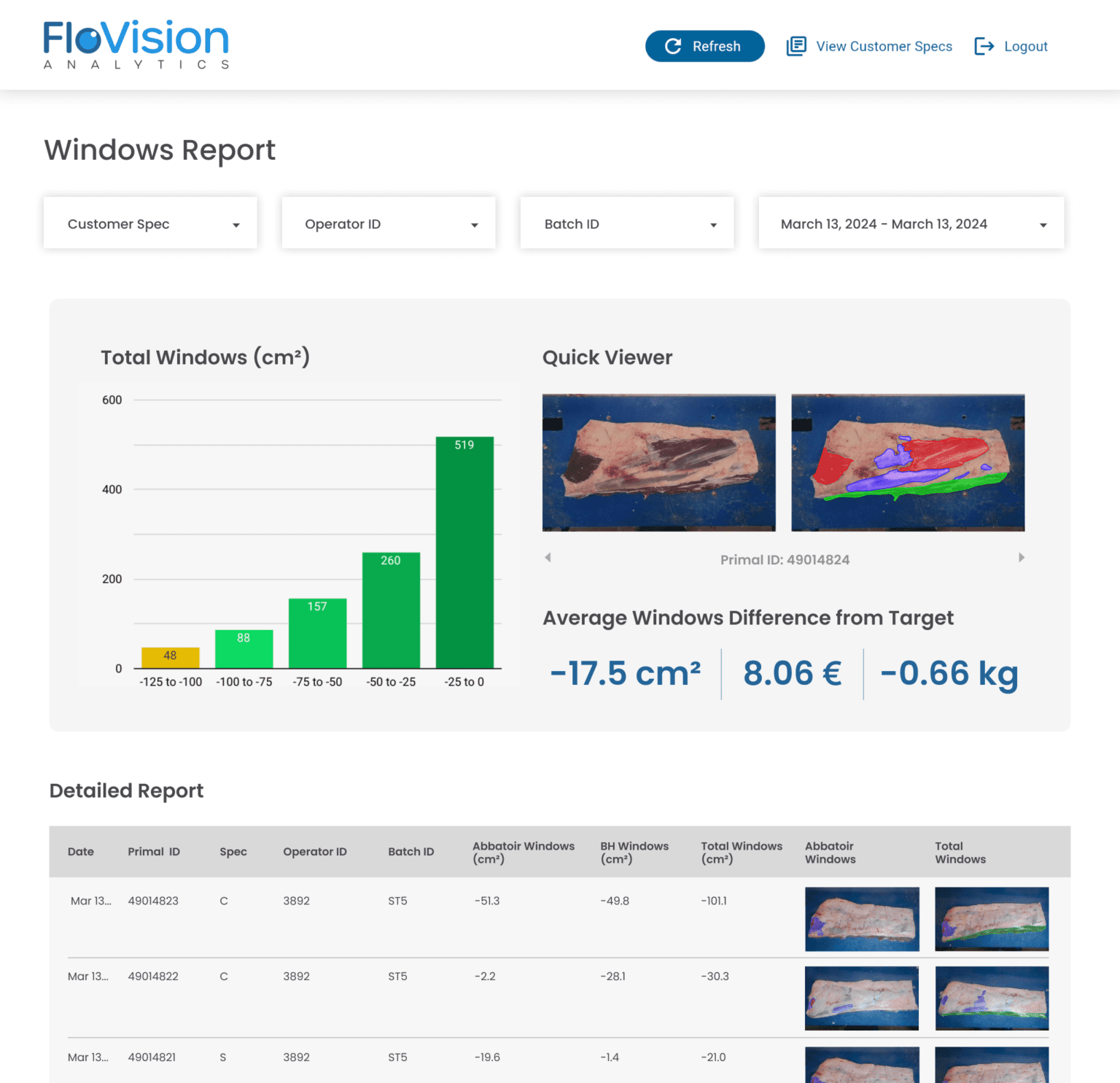

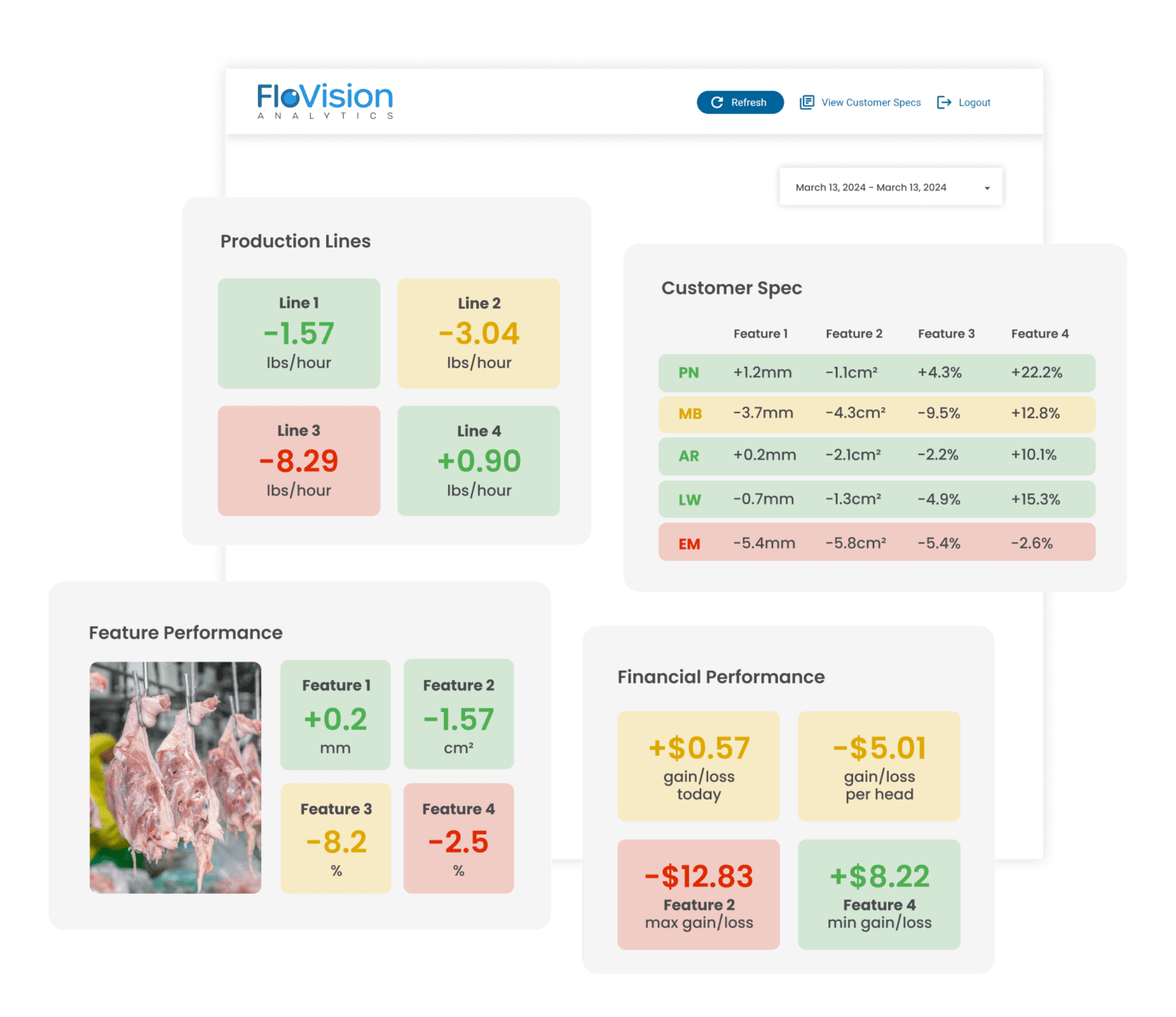

FloVision Analytics

Yield, quality, financial, and staff performance data is organized into clear visualizations in the FloVision Analytics dashboard. Supervisors and managers can quickly review reports and trends for staff, customers, production lines and facilities, automatically receive updates via email, and integrate data seamlessly with APIs.

Beef processor increases spec accuracy by 30%

- Recovered Yield - FloVision Pro uncovered a striploin primal spec that was overtrimmed by 120% on average

- Performance Improvement - Butchers used laser guides to achieve consistent spec trimming

- Bottom Line - The processor recovered $68,400 yearly by correcting this error