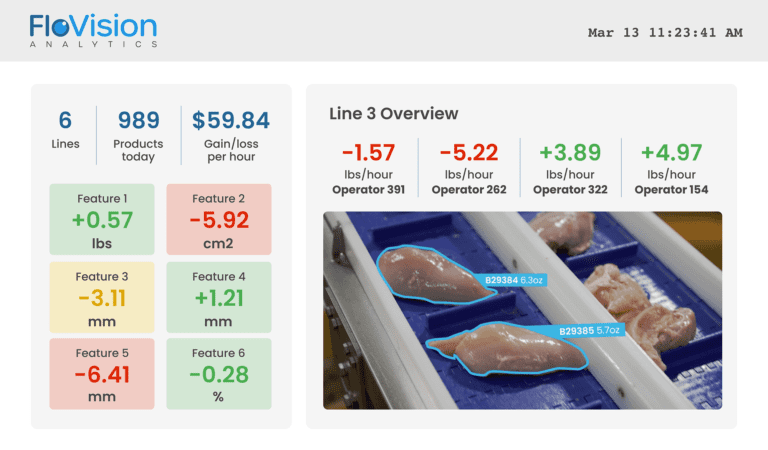

Compact AI sensor to measure yield and quality at production speed

Understand food performance by measuring the most important features, unlocking yield and QA analysis, KPI reporting, and benchmarking of site operations.

Yield

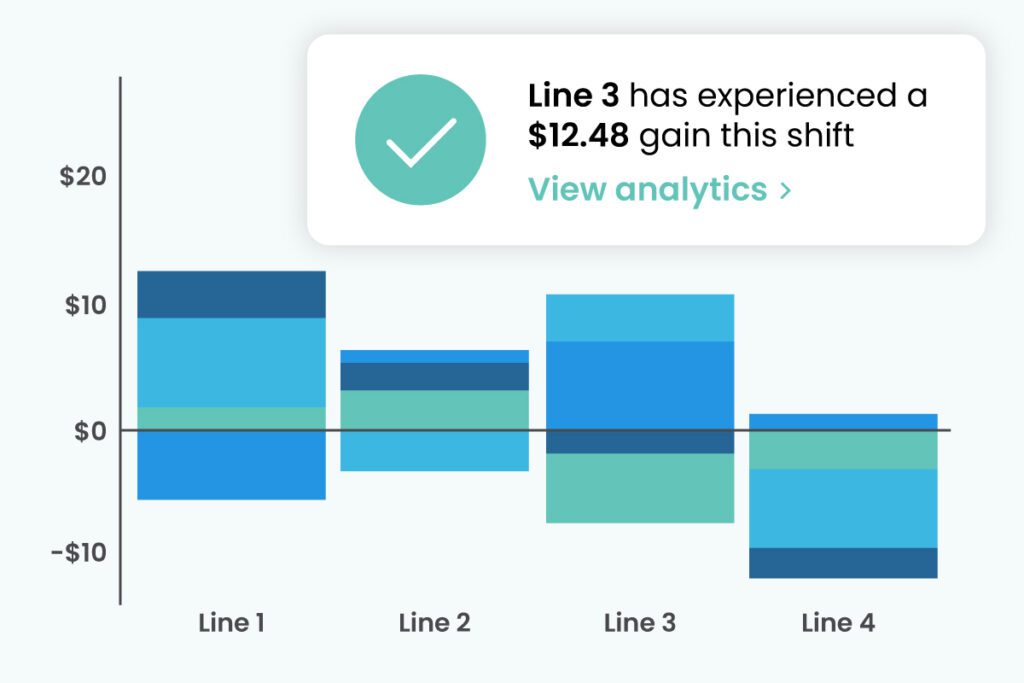

Identify gain and loss trends with product and financial reports.

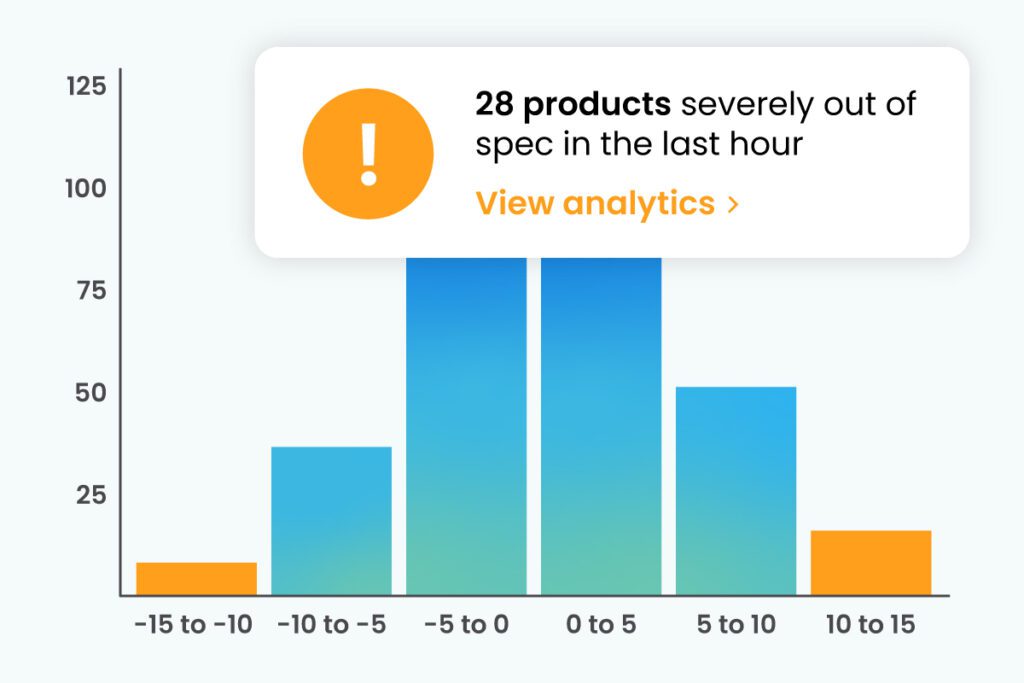

QA

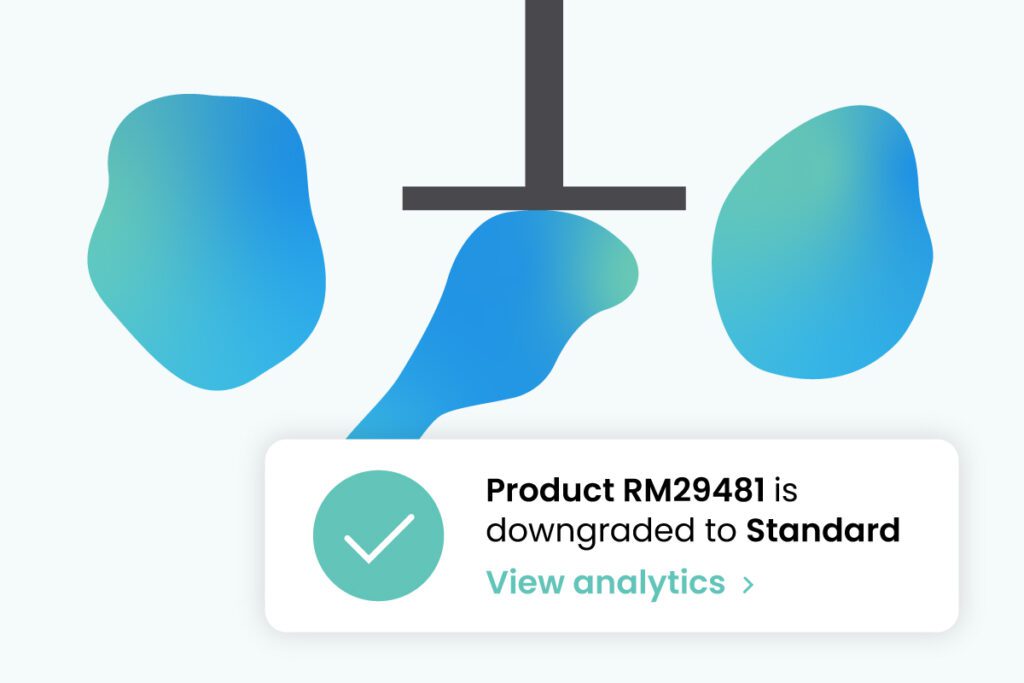

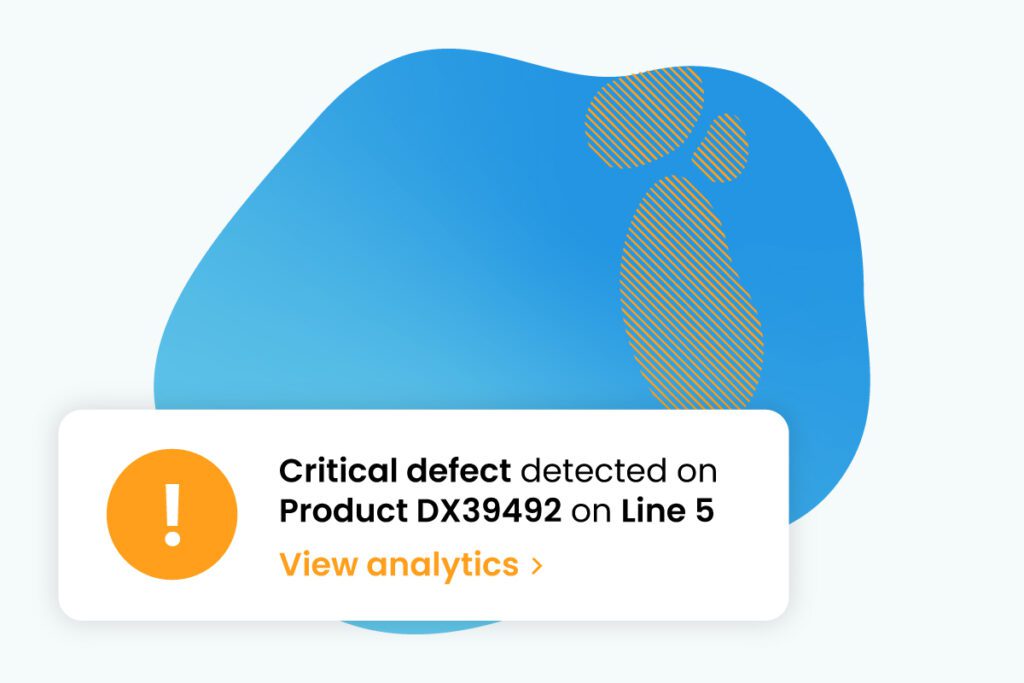

Grade and classify food products, identify defects and errors, and automatically sort, regrade, or reject products in real-time.

traceability

Analyze your process by piece, instead of by batch, without intrusive sensors or paper labels.

flexibility

With a near-zero footprint, FloVision Nano can mount to existing hardware in any area of your facility and be installed with no production downtime.

FSQA Supervisor, Poultry Processor

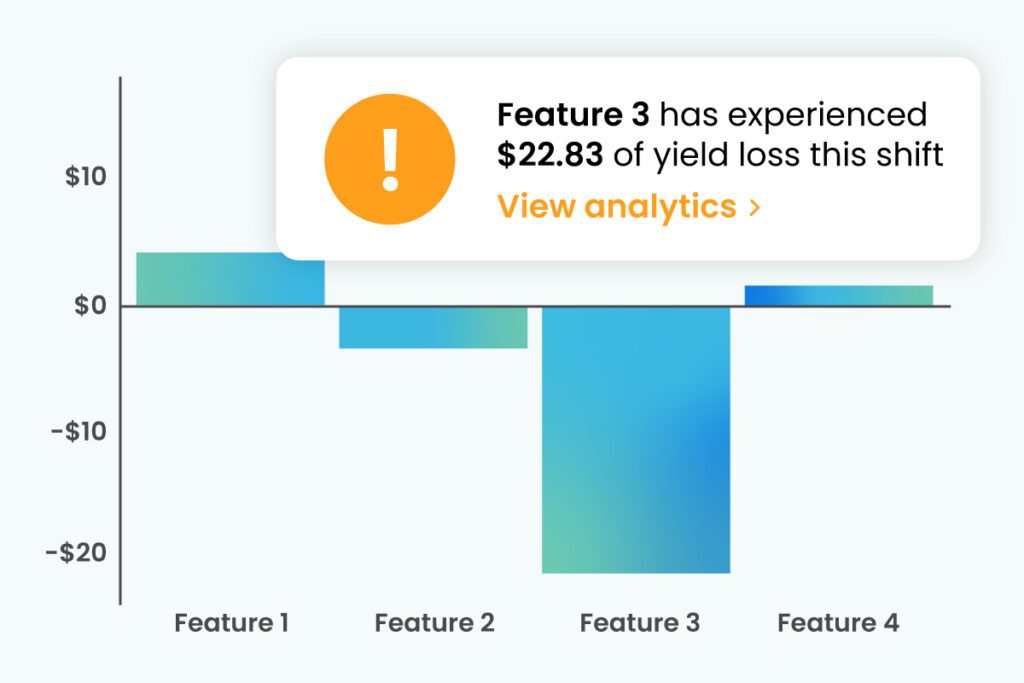

Yield Analysis

QA Analysis

Automated Sorting

Financial Analysis

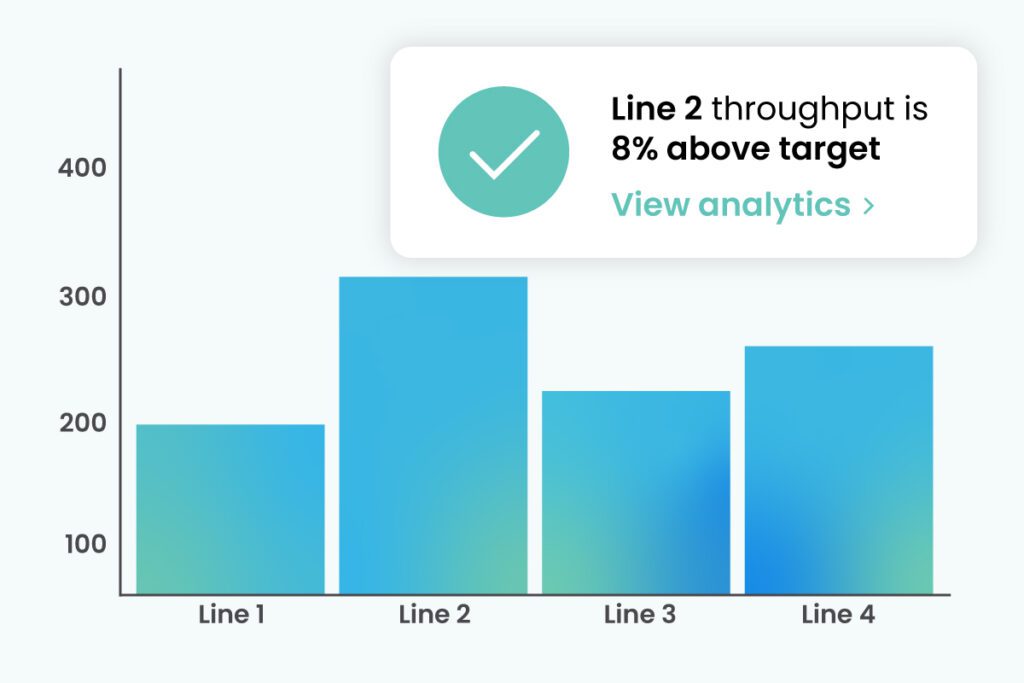

Productivity Analysis

Defect Detection

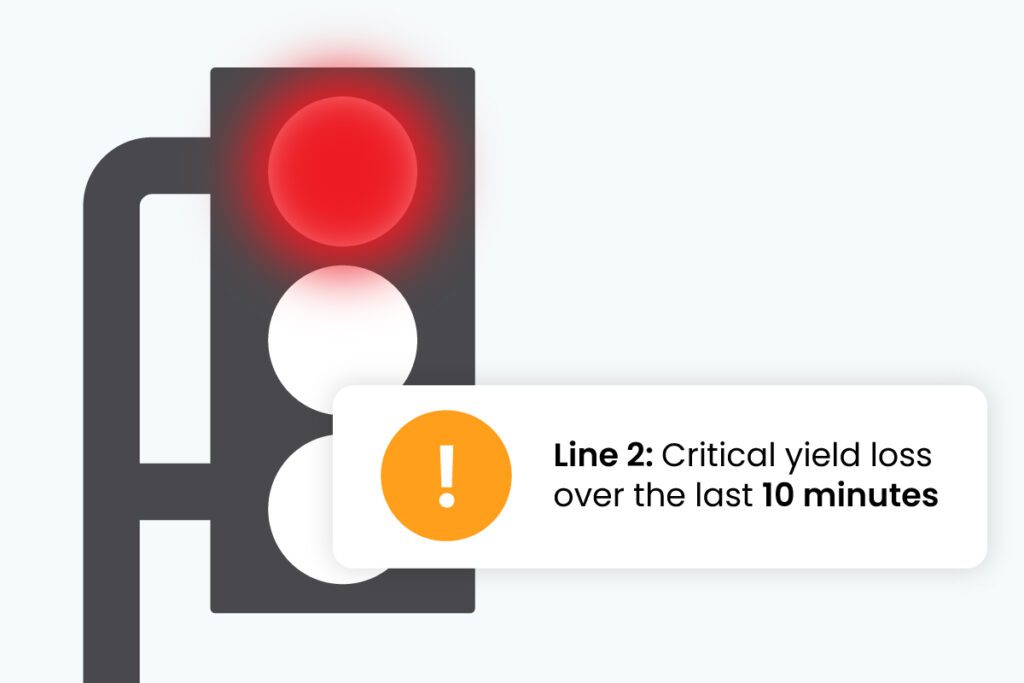

Supervisor Alerts

Specification Measurement

Foreign Body

Grading & Classification

Traceability

Label Reading

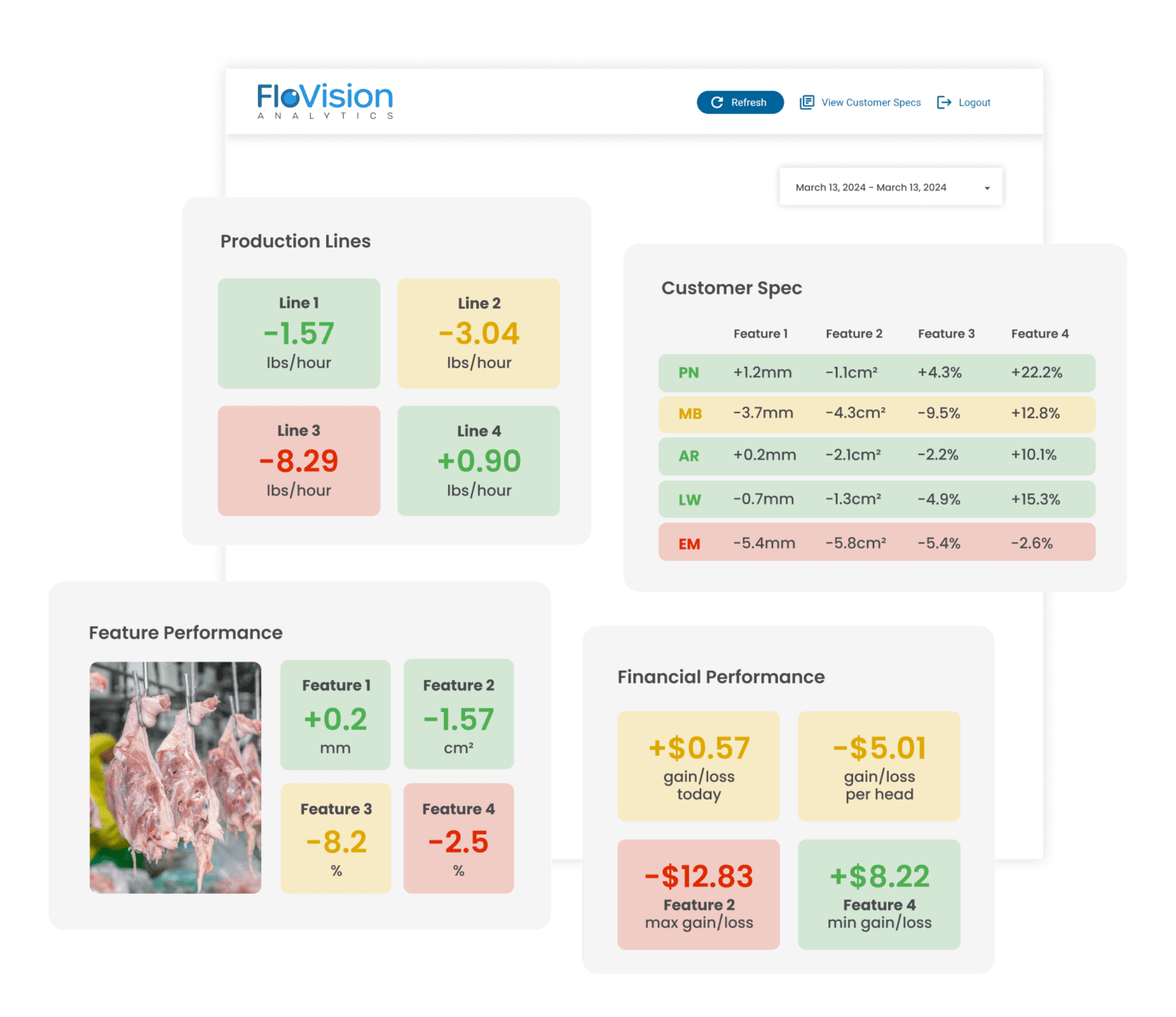

FloVision Analytics

Yield, quality, financial, and staff performance data is organized into clear visualizations in the FloVision Analytics dashboard. Supervisors and managers can quickly review reports and trends for staff, customers, production lines and facilities, automatically receive updates via email, and integrate data seamlessly with APIs.