Production Managers Boost Striploin Yield by $2/Head

A major beef processor partnered with FloVision Solutions to identify financial opportunities and enhance staff efficiency in striploin primal production lines. They installed the FloVision Pro, which used spec optimization and supervisor alerts to reduce striploin overtrimming by 6.25%, resulting in an average yield increase of $2.02 per head.

Yield Analysis

Specification Optimization

Financial Analysis

Supervisor Alerts

Challenge

The striploin primal, one of the most valuable cuts of beef, features a fat side facing the hide and a lean side facing the ribs. In the boning hall, staff separates primals from the carcass; they aim to maximize the fat on both sides of the primal to increase weight and avoid wasting yield left on the hide and ribs. Station butchers remove bones and trim to company and customer quality specifications.

This beef processor produces 300 head per shift at a single plant, and cuts are processed in a fast-paced, multi-step production line. Station butchers were trained to trim a small amount of additional fat from the lean side of the striploin primals, but were consistently overtrimming this area. Supervisors had little time or visibility to monitor each butcher to identify this error and retrain them on this technique. As a result, this plant lost $2.02 per head on on lean side striploin primal overtrimming.

Solution

The beef processor started using the FloVision Pro at several striploin primal stations. The FloVision Pro features sensors that measure primal features, real-time operator and supervisor alerting, and a manager dashboard with data and trend analytics.

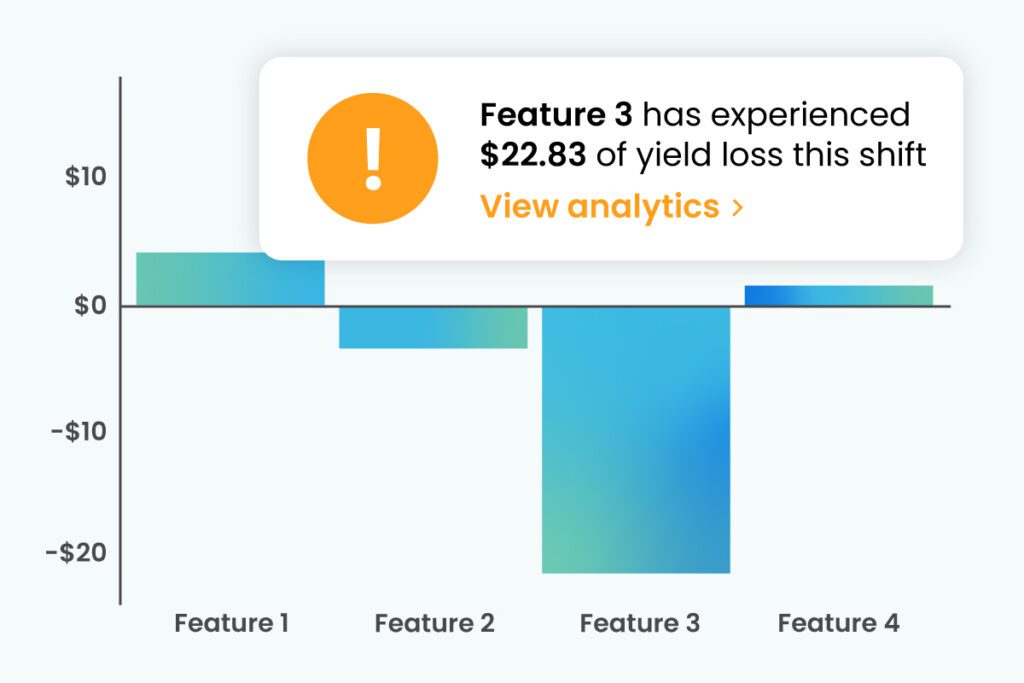

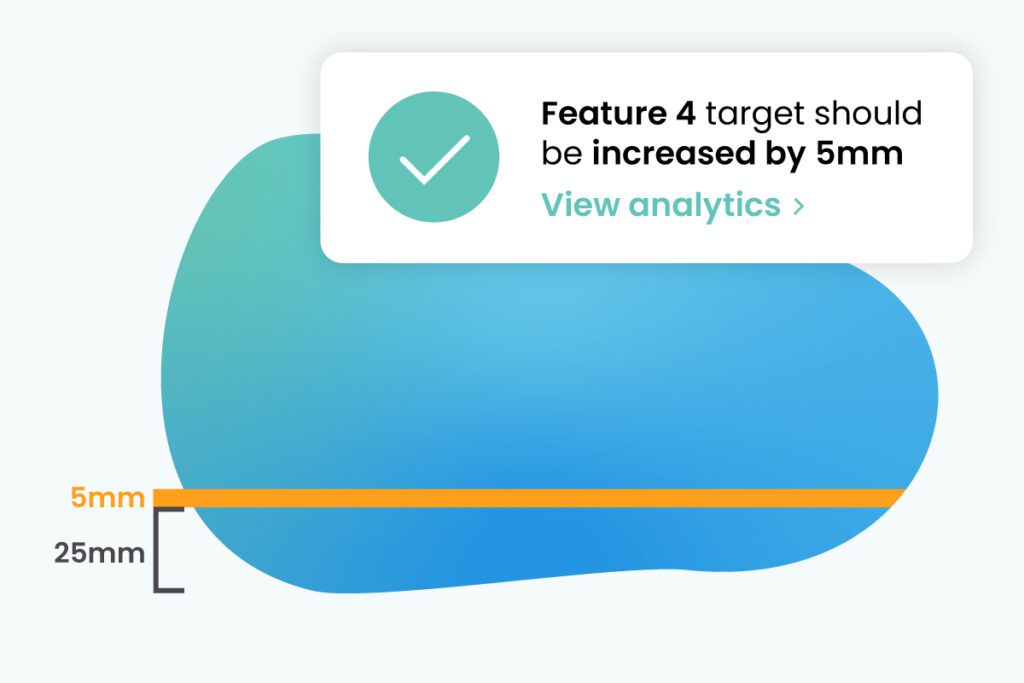

FloVision Pro automatically scanned and measured each primal before and after station butchering. The system compared the fat area and weight of the striploin primal in these two scans and identified that station butchers were regularly overtrimming the lean side and could optimize this feature by leaving more fat.

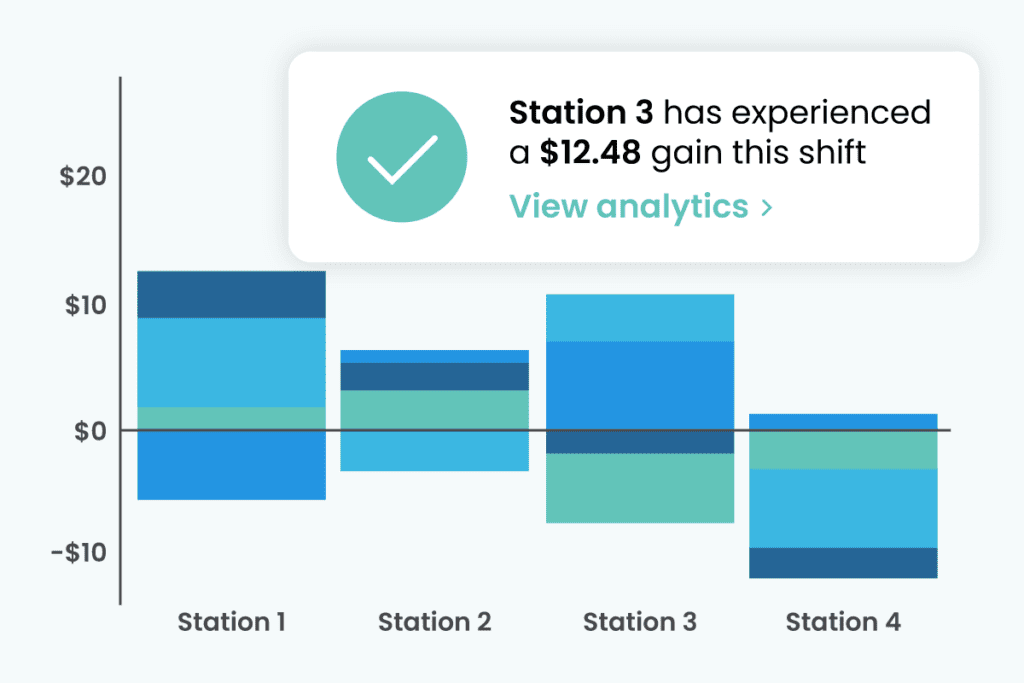

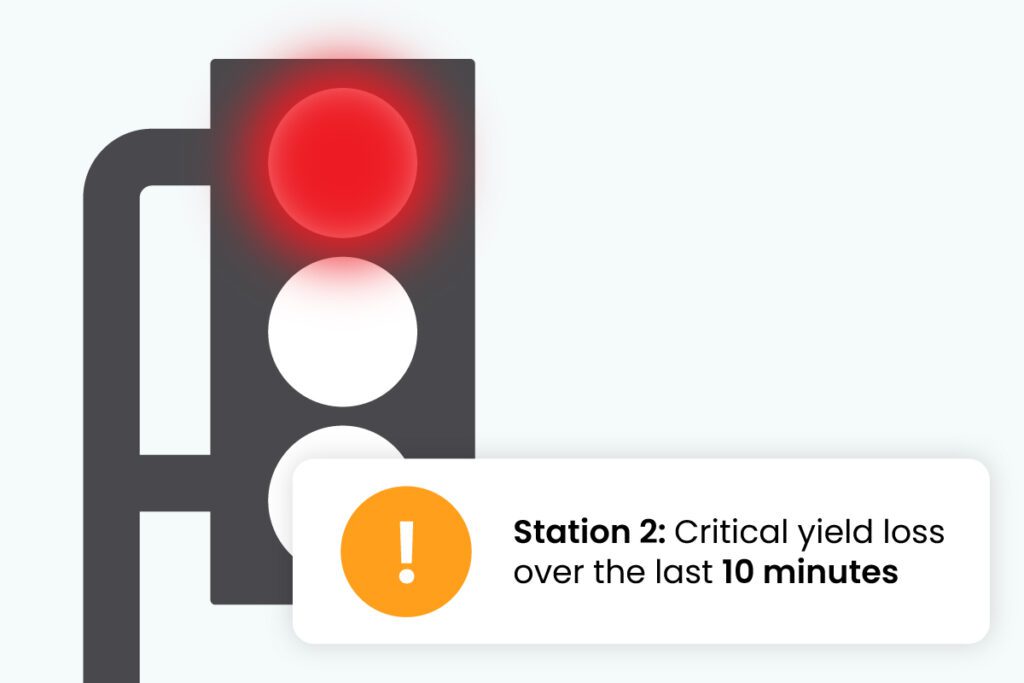

The FloVision Analytics manager dashboard notified floor and station managers of this trend and created on-floor alerts for butchers and supervisors. When butchers overtrimmed, they received alerts on the FloVision Pro operator screen, while supervisors were signaled with a light whenever the striploin lean side was overtrimmed beyond a specific threshold.

Results

The FloVision Pro helped this beef processor to increase their bottom line and increase production speed. The striploin lean side overtrimming resulted in a $2.02 yield loss per head. Reducing the amount of trimming needed per primal also sped up production by 4 seconds each, resulting in a 6.7% in striploin production speed overall.

"FloVision Pro allows us to see the big picture of our operations. It measures the trimming errors made by our butchers and shows us the financial value of them, and we can set alerts for areas of concern so we can step in quickly."

Line MANAGER