The Need for Sustainable Food Production

Conventional food production methods often lead to excessive resource consumption and high levels of waste, which contribute to environmental concerns. Globally, 25–30% of total food produced is lost or wasted and food waste is estimated to contribute 8-10% of total manmade greenhouse gas emissions. As the food industry moves toward more sustainable practices, the integration of technology becomes critical. Food technology and quality control plays a pivotal role in addressing these challenges, enabling more efficient and environmentally friendly production methods.

Sustainability in food production is not just about meeting current demands but also ensuring that future generations have access to sufficient, safe, and nutritious food. This requires a shift toward practices that minimize environmental impact, optimize resource use, and reduce waste. Technologies like AI and computer vision are key to achieving these goals, offering innovative solutions that enhance food yield and quality without added human effort.

Understanding AI and Computer Vision in Food Production

AI and computer vision are two of the most transformative technologies in food industry applications. AI, or artificial intelligence, refers to the capability of machines to learn from data, make decisions, and improve over time. Computer vision, a subset of AI, involves the use of cameras and algorithms to interpret and understand visual information from the world.

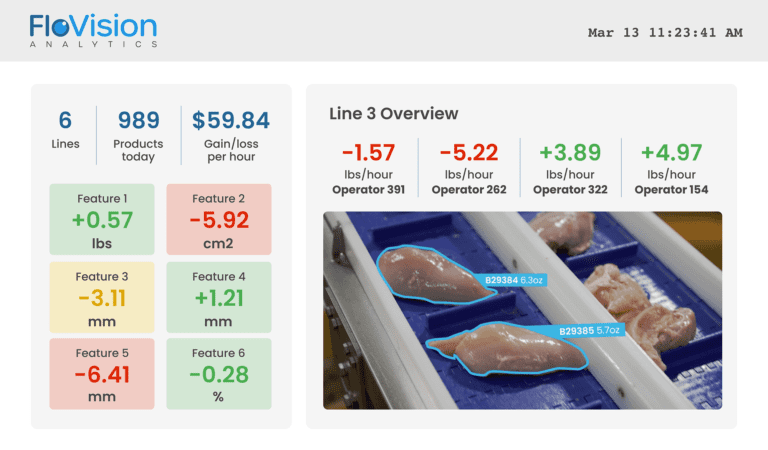

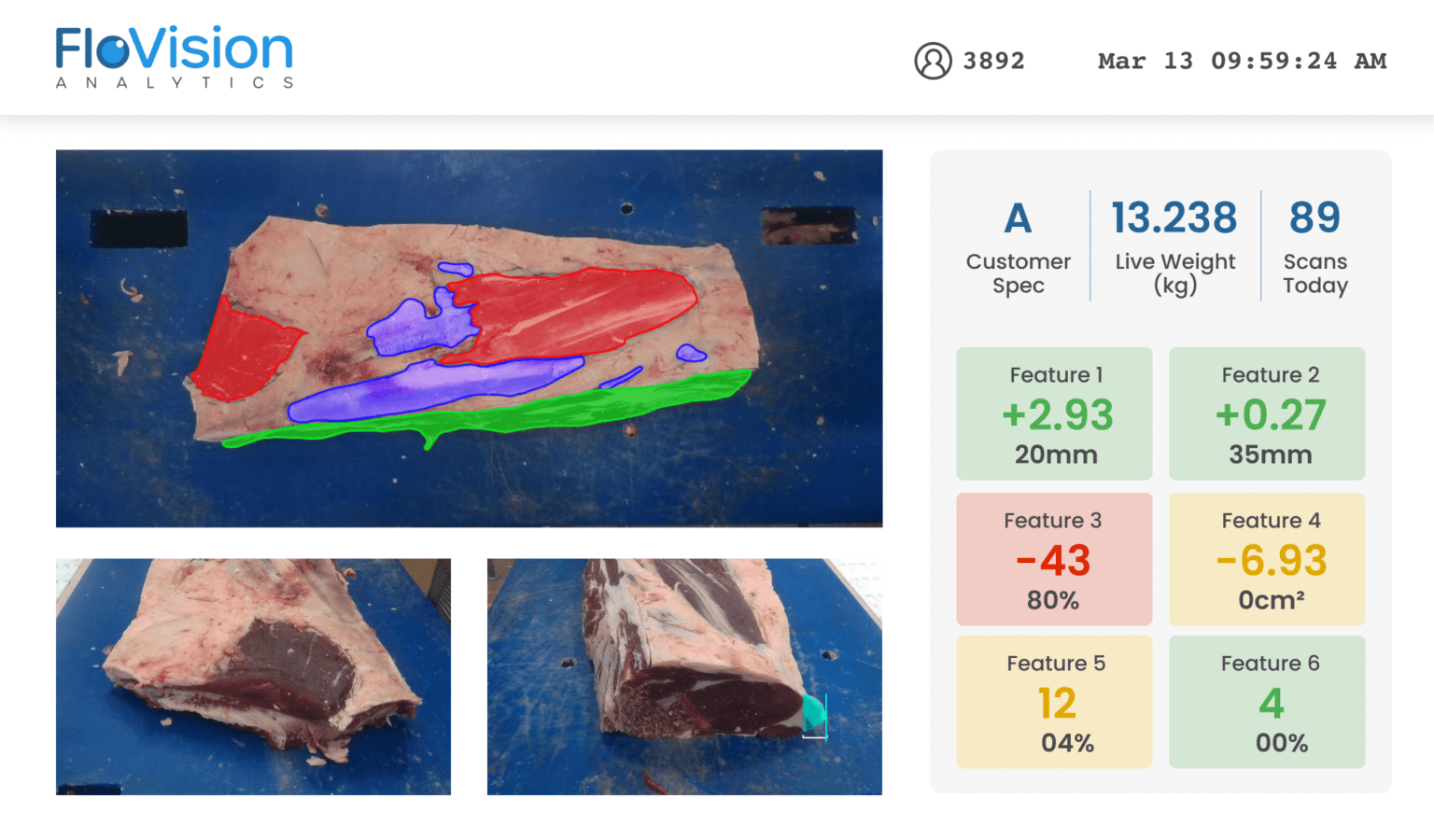

These technologies are applied at various stages of food production, from sorting and grading raw materials to monitoring and ensuring the quality of finished products. For instance, AI algorithms can analyze data from sensors and cameras to detect defects, classify products, and optimize facility resources. Computer vision systems can inspect food items in real-time, identifying imperfections and ensuring they meet quality standards. Together, AI and computer vision make food production more efficient and reliable.

Sustainability in food production is not just about meeting current demands but also ensuring that future generations have access to sufficient, safe, and nutritious food.

Enhancing Yield Using Food Technology and Quality Control

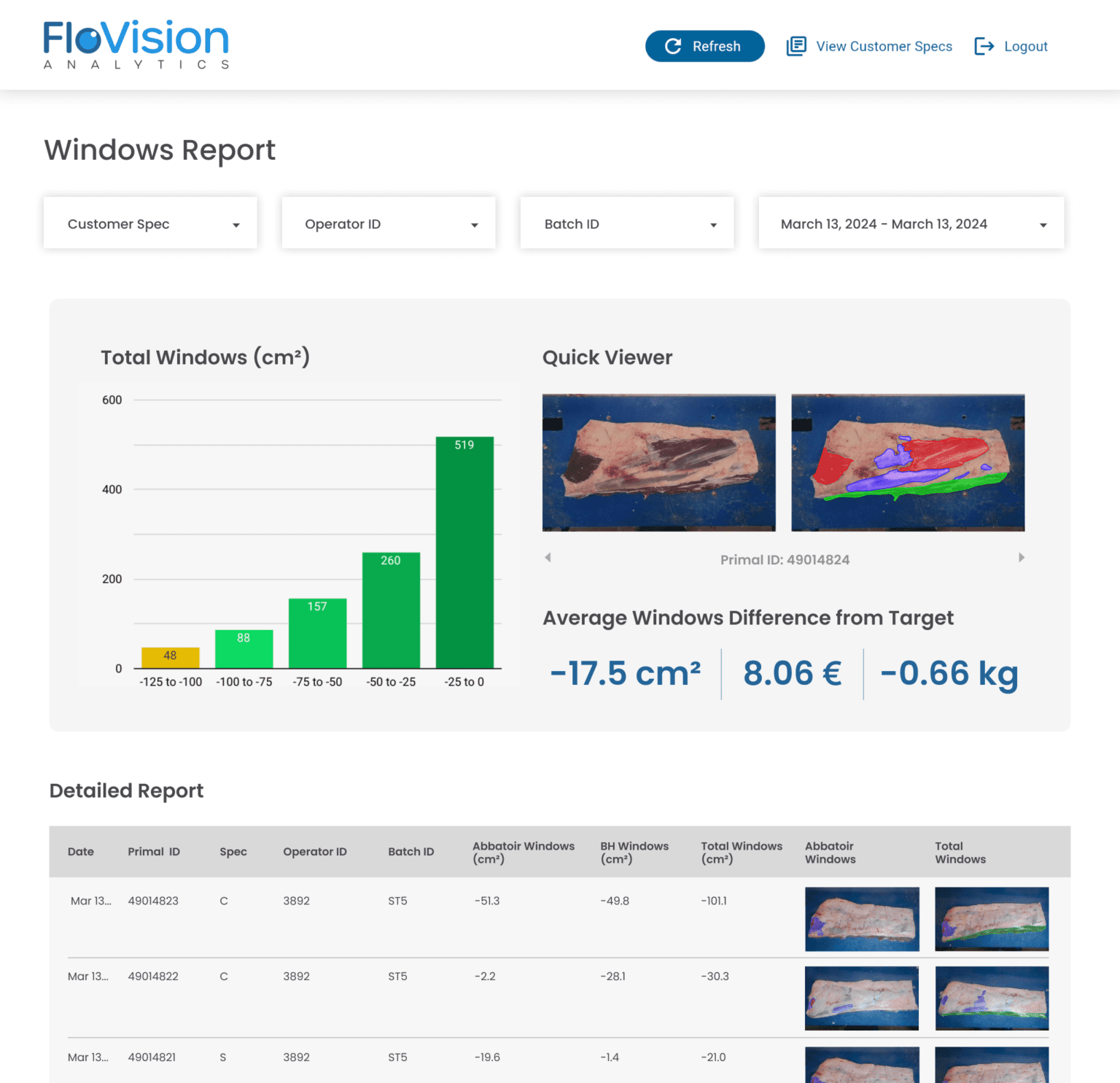

One of the most significant benefits of integrating AI and computer vision into food production is the ability to enhance yield and reduce waste. In traditional food production, a considerable amount of produce is discarded due to imperfections or inefficiencies in the sorting and grading processes. However, using AI and computer vision, these products can be sorted more accurately and imperfections can be easily identified and addressed. These advancements in food technology and quality control ensure that more food reaches consumers while minimizing waste. The economic and environmental benefits of reducing waste are substantial. Less waste means fewer resources are needed for production, leading to lower costs and a smaller carbon footprint. An estimated 840 million people will face severe food insecurity by 2030, an increase from roughly 746 million people in 2019. By maximizing yield, producers can address this demand more efficiently and contribute to food security and sustainability.Improving Quality Control and Safety

Ensuring that products meet stringent quality standards and are safe for consumption is essential for maintaining consumer trust and protecting public health. With real-time monitoring capabilities, AI and computer vision systems can detect quality issues as they occur, allowing for immediate corrective actions. For instance, these technologies can identify contaminants, spoilage, or defects in food products, ensuring that only high-quality items reach consumers. This level of precision and speed is unmatched by traditional methods, making AI and computer vision a critical element of food technology and quality control. Moreover, these technologies help ensure compliance with regulatory standards. By providing detailed and accurate data on product quality, they assist producers in meeting the requirements set by food safety authorities and avoid recalls. According to the Grocery Manufacturers Association in the U.S., 52% of all recalls cost over $10M and 23% cost over $30M. Implementing these technologies help companies prevent these costly recalls and reputation damage.Resource Efficiency

Another critical aspect of sustainable food production is the efficient use of energy and resources. AI-driven optimization plays a vital role in achieving this goal. By analyzing data from production processes, AI can identify areas where resources are being used inefficiently and suggest improvements. For example, AI can identify where water and energy are used in food processing plants, then indicate areas to reduce consumption and lower costs.

By minimizing waste and optimizing resource use, AI and computer vision help lower greenhouse gas emissions, supporting global efforts to combat climate change. This intersection of food technology and quality control with environmental sustainability highlights the transformative potential of these tools.

Traceability and Transparency

In today’s market, traceability and transparency are increasingly important to consumers. According to a recent study, 72% of consumers consider transparency important when deciding on food brands and retailers. People want to know where their food comes from, how it was produced, and whether it meets ethical and environmental standards. AI and computer vision technologies enhance traceability by providing detailed information about the entire production process.

From farm to table, these technologies can track and document every step of production. This meets consumer demands and helps producers identify and address issues more quickly. Enhanced traceability makes it easier to uncover the source of any problems, emphasizing the role of food technology and quality control in ensuring safe and reliable food production.

Challenges in Food Technology and Quality Control

Despite the many benefits, implementing AI and computer vision in food production comes with challenges. These can include initial costs, the need for new equipment, and resistance to change within the industry. However, solutions are available to overcome these obstacles.

For instance, companies can start with pilot projects to demonstrate the value of these technologies before scaling up. Processors can implement solutions with a near-zero footprint in their facilities, like FloVision Nano, which mounts to current facility equipment to provide AI and computer vision analysis on throughput. Partnerships with technology providers can offer ongoing support and innovation, facilitating smoother integration of these technologies.

According to a recent study, 72% of consumers consider transparency important when deciding on food brands and retailers.

Future Trends in Food Technology and Quality Control

Looking ahead, several emerging trends and advancements in AI and computer vision promise to further enhance food production sustainability. Advancements in machine learning algorithms, improved sensor technologies, and greater integration of data across the supply chain are all on the horizon with these emerging technologies.

For example, future AI technology may be able to use predictive analytics to forecast and prevent production or product issues before they occur. Improved sensors and imaging technologies will enhance the accuracy and speed of quality control measures. Greater data integration will enable more comprehensive and real-time insights into production processes, driving continuous improvements in efficiency and sustainability. In the “AI in Agriculture” sector alone, the global market is expected to grow from 1.5B USD in 2023 to 10.2B USD by 2032.

By making food production more efficient, sustainable, and transparent, AI and computer vision can help address some of the most pressing challenges facing the global food industry today.

Food Industry Sustainability with AI and Computer Vision

AI and computer vision technologies are revolutionizing food production by enhancing sustainability and reducing environmental impact. Through improved yield, reduced waste, enhanced quality control, and greater resource efficiency, these technologies are transforming the industry. By embracing emerging technologies, producers can ensure a more sustainable and efficient future for food production.

As we move forward, it is crucial for industry stakeholders to continue investing in and adopting these advanced technologies. The benefits are clear: improved sustainability, better quality control, and a more resilient food production system. Together, we can build a future where food technology and quality control lead the way to a more sustainable and efficient food industry.

FLOVISION NANO

Compact AI sensor to measure yield and quality at production speed.