What Drives Yield Loss in Pork Processing? A Closer Look

Butchering Inaccuracies In the high-paced demands of the processing line, butchers commonly trim off too much meat, resulting in lost high-value yield. This excessive removal reduces the volume of pork product, directly cutting into potential revenue. On the other hand, insufficient trimming of certain features can also lead to lower quality meats that fail to meet customer specifications. These products often obtain a lower price or may be rejected outright by customers, leading to further financial losses. Balancing the fine line of optimal trimming is crucial, as it affects both the quality and quantity of pork. Beyond meeting customer specs, there are additional processes in pork production that affect yield. For instance, butchers might remove excess meat that does not negatively affect product quality but could contribute to a higher overall weight. However, without precise cutting techniques and a thorough understanding of the varying grades and specs required by different customers, valuable parts of the pork that could increase product weight and value are often discarded unnecessarily. The ability to optimize each spec for maximum yield without compromising quality is an essential tool to significantly reduce waste and increase profit margins in pork processing operations from 1-3% to 3-5%.

The ability to optimize each spec for maximum yield without compromising quality is an essential tool to significantly reduce waste and increase profit margins in pork processing operations from 1-3% to 3-5%.

Undetected Errors In pork processing facilities, undetected production errors are a significant barrier to maintaining high yield and ensuring product quality. Butchers do most of their work without immediate performance feedback, meaning they are typically not alerted to incorrect trimming or opportunities for yield optimization. This absence of immediate feedback allows errors and inefficiencies to compound over time, as butchers unknowingly replicate them. Adding to this issue is the limited number of floor and station managers available to oversee the pork production. These managers are crucial for catching and correcting errors in real-time, yet they are often responsible for monitoring multiple stations or lines simultaneously. This spread of attention can make it difficult for them to observe and address every mistake as it happens. As a result, many unaddressed errors amplify over time, leading to substantial yield losses and affecting the profitability of the entire operation.

Improperly Sorted Products

Improper sorting of pork products leads to significant yield loss, particularly when the sorting is not optimized to meet the specifications required by customers. Butchers and processors who fail to align their products according to these precise customer specifications often end up with batches of meat that are less valuable or unsuitable for their intended customer. This misalignment can force processors to sell these products at a discount. The optimization of product sorting is crucial as it ensures that each piece of meat is processed and categorized to maximize its market value and match customer expectations, thereby minimizing waste and enhancing profitability.

Lack of Traceability

Without systems to track the origin and quality of incoming pork, processors cannot identify which producers consistently provide livestock with the best yield. This leads to continued reliance on suppliers whose products result in lower yields, compounding the yield loss from butchering and improper sorting. Effective traceability allows processors to optimize their supply chains, choosing sources that improve overall yield, quality, and profitability.

Proven Techniques to Improve Yield in Pork Production

Individualized Butcher Training

To effectively address yield loss, pork processors can strengthen the skills of their butchers through individualized training programs. Training should be tailored based on specific performance metrics and common errors identified during the butchering process. By analyzing each butcher’s technique and outcomes, training can be customized to address particular weaknesses and improve production efficiency. FloVision Solutions supports this process by measuring individual butcher performance over time, providing managers with trend analysis that helps in developing personalized training strategies for each butcher.

Real-Time Performance Feedback

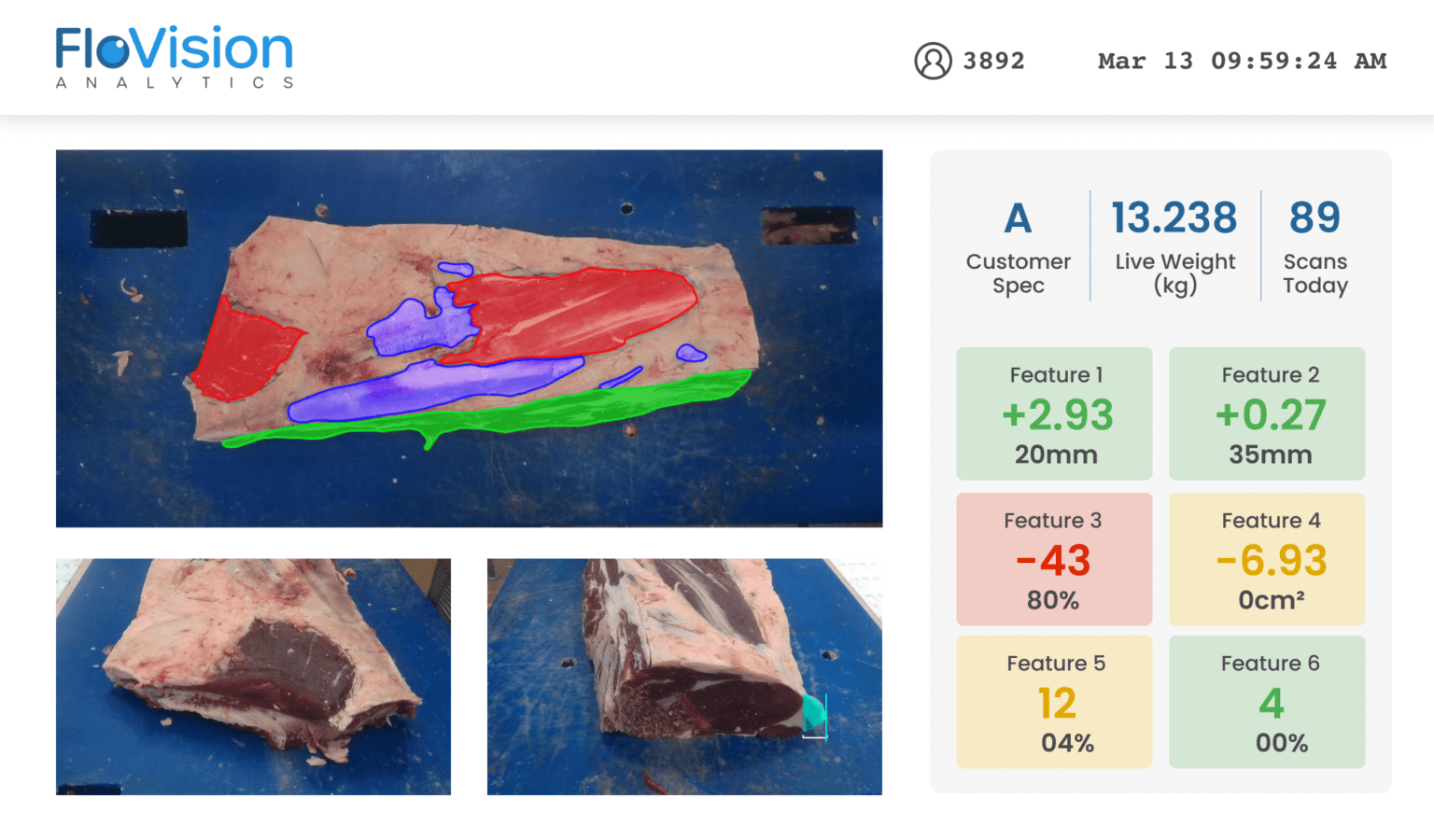

Implementing technology that measures specific pork features and weight at the time of butchering can significantly enhance the immediate feedback provided to butchers. These systems enable butchers to receive instant performance feedback, helping them to adjust their techniques in real-time. FloVision Pro, for instance, utilizes lasers to guide butchers during the trimming process and displays real-time feedback on station screens. This system guides butchers to eliminate over and under-trimming and highlights areas where yield optimization can be achieved, ensuring that each cut maximizes value and meets quality standards.

FloVision Pro guides butchers to eliminate over and under-trimming and highlights areas where yield optimization can be achieved, ensuring that each cut maximizes value and meets quality standards.

Automated Product Sorting

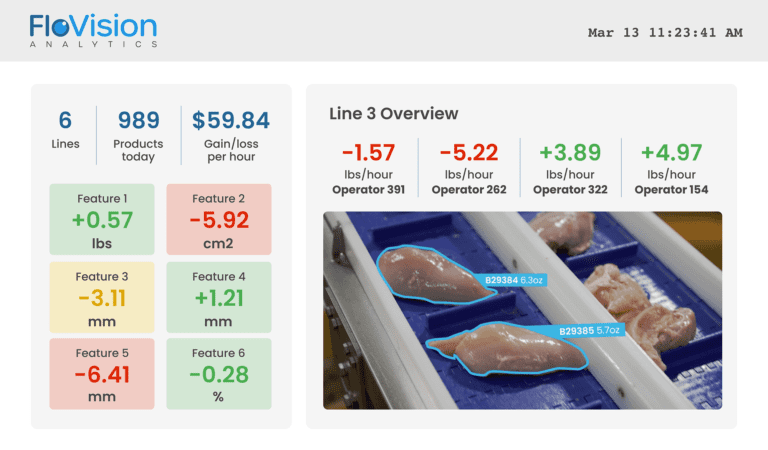

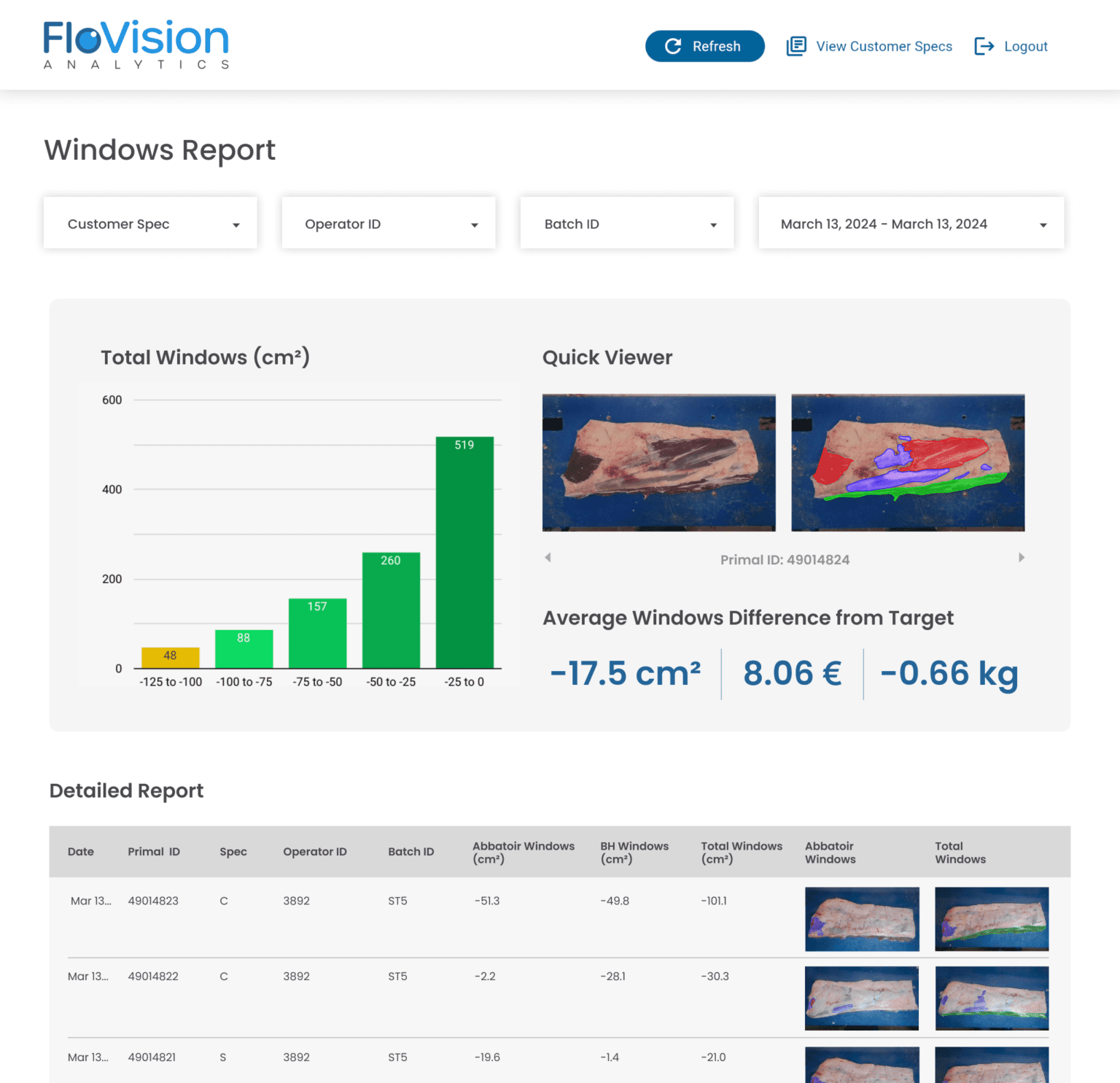

Utilizing automated sorting systems can transform how pork products are categorized during processing. These systems scan each product and automatically sort them by grade, dimension, or other quality metric, and assign them to the best customer spec. FloVision Nano enhances this process by providing automated sorting and grading insights for each piece as it moves along the conveyor. This technology ensures that every piece of pork is assigned to maximize yield and reduce human error.

Traceability

Traceability systems are crucial for pork processors to maintain oversight throughout production facilities. By tagging or using advanced fingerprinting technology, processors can track each piece from slaughter through each stage of processing. This capability allows for the identification of the suppliers, batches, and butchers that contribute to the highest quality end products. FloVision Solutions provides processors with fingerprinting technology that tracks products throughout the production process without any physical tagging and provides supplier, batch, and butcher trend data.

Converting Pork Yield Loss into Profit

Yield loss in pork processing is a complex issue that has sources across the production chain and directly affects the profitability of pork processors. FloVision Solutions offers technology that addresses the common causes of yield loss, including performance measurement, production trend analysis, and product traceability. By partnering with FloVision, pork processors can overcome these challenges and transform their operational efficiency and profitability.

For more information on how FloVision Solutions can help you maximize yield and reducing waste at every step of pork production, get in touch.

FLOVISION NANO

Compact AI sensor to measure yield and quality at production speed.