Understanding Supply Chain Visibility at the Plant Level

Supply chain visibility means knowing where your materials are, when they’ll arrive, and how they affect your production plans. It gives teams a clear view of everything from orders to line use.

In the past, visibility was mostly a concern for purchasing or logistics. Today, it plays a direct role in how production teams plan and adjust. Real-time updates help teams manage batching, labor, and staging without guessing or scrambling at the last minute. Companies that implement real-time tracking technologies are 68 percent more likely to report improved visibility and better inventory control, according to Food Safety.

In fast-paced environments, this kind of insight is key. It helps reduce surprises and keeps handoffs between teams running smoothly.

Common Disruptions That Visibility Can Help Avoid

Production delays can come from many sources—most of them avoidable with better visibility:

- Late packaging materials that prevent sealing or staging

- Missing or delayed raw materials that pause batching

- Bulk items that run low without warning

- Products that don’t meet spec, slowing down QA

- Wrong lead time estimates that cause missed or extra orders

- Manual supply checks that take time and may miss details

These problems create uncertainty in systems that depend on speed and accuracy. With better visibility into supply and supplier performance, teams can catch issues early and make smarter choices.

Companies that implement real-time tracking technologies are 68% more likely to report improved visibility and better inventory control

What Visibility Gaps Really Cost

Without real-time, reliable data on incoming supplies, teams are left to guess. That leads to reactive decisions and more disruption. Here’s what that can cost:

- Downtime, when production stalls waiting for materials

- Staff rework, when poor-quality products delay progress

- Waste, especially when chilled items sit too long

- Higher inventory costs, caused by over-ordering to be safe

- Labeling or compliance mistakes, from last-minute changes

Better supply chain visibility doesn’t stop all problems—but it gives your team the tools and time to handle them early.

Four Practical Ways to Improve Supply Chain Visibility

You don’t need a full technology upgrade to make progress. Small, focused changes—especially around the materials that often cause delays—can make a big impact.

1. Consolidate Supply and Inventory Information

When purchasing, receiving, and production teams use different tools or spreadsheets, delays are hard to catch. A shared dashboard or ERP keeps everyone working from the same information, making it easier to plan production runs, avoid repeat orders, and fix issues early.

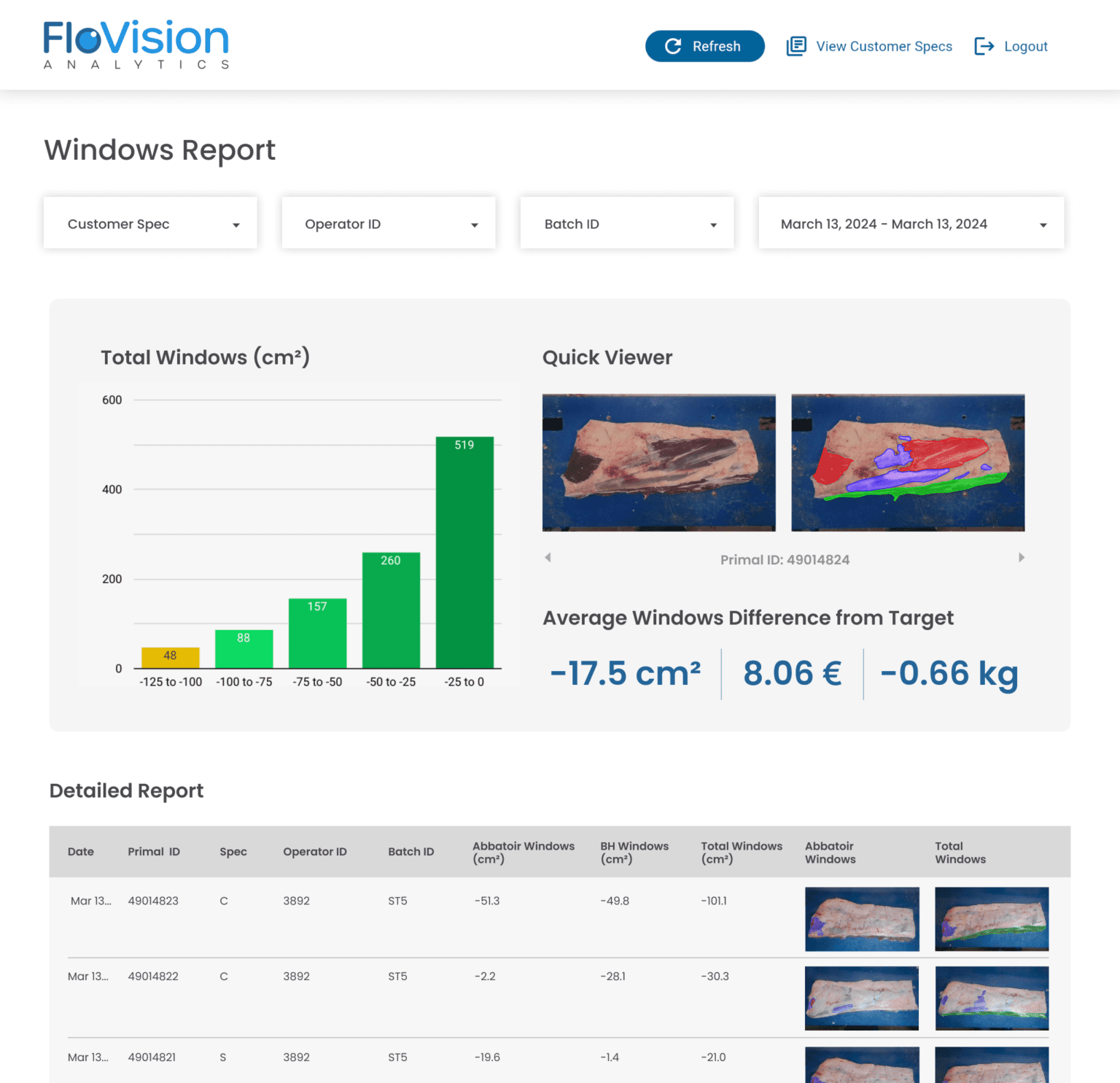

2. Use Traceability to Flag Supplier or Quality Issues

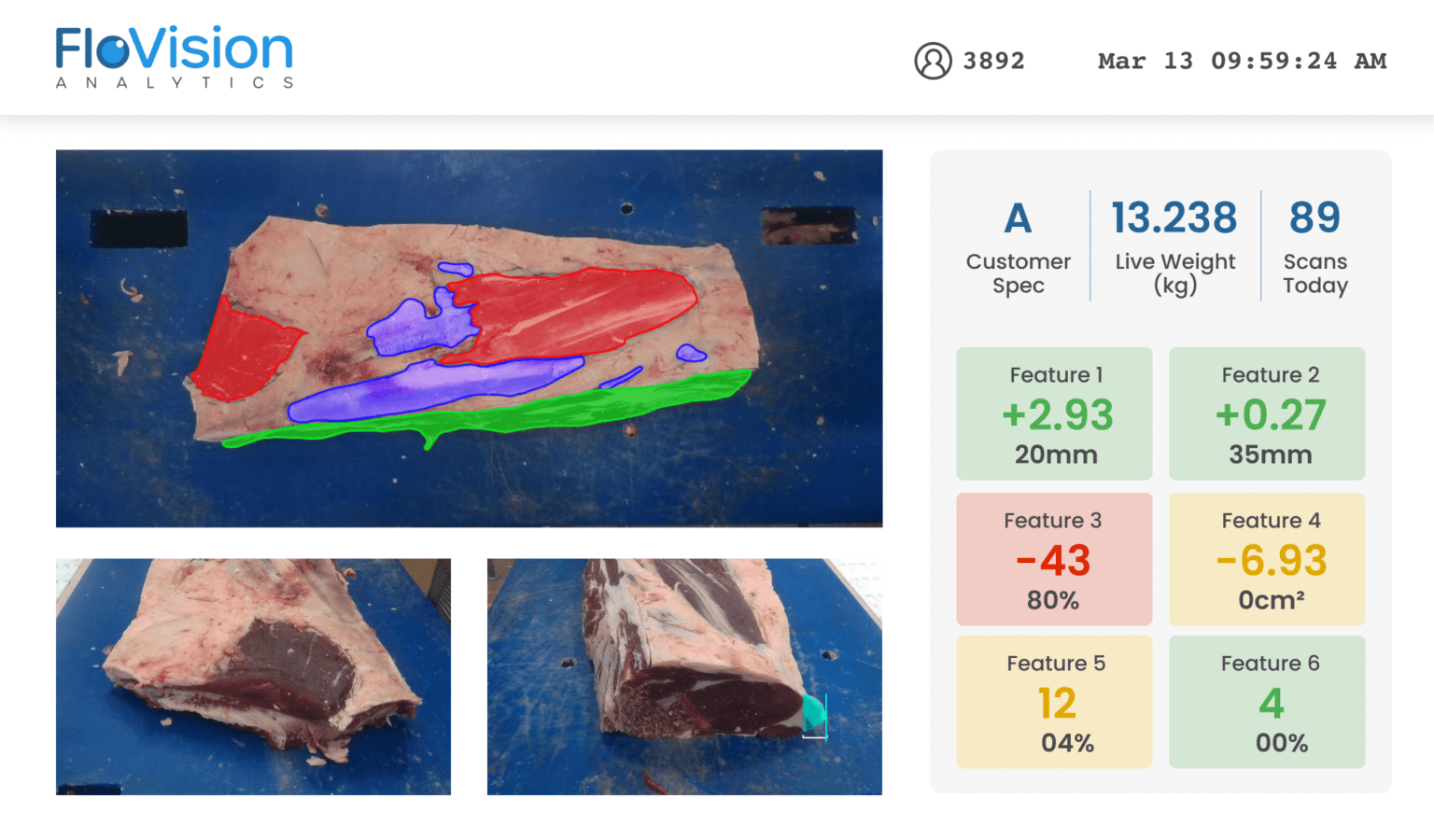

Not all problems come from delays—some come from poor-quality materials. Lots that don’t meet standards can slow down QA or lead to waste. FloVision Nano helps track which products from suppliers often cause issues. This helps teams make better sourcing decisions and get ahead of problems before they affect the line.

3. Sync Production Plans With Real-Time Supply Updates

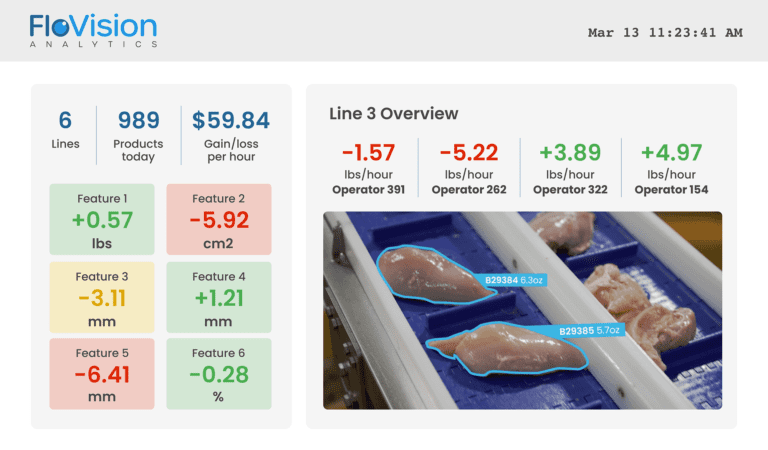

Having materials isn’t enough—what matters is how smoothly they move through production. Real-time data helps teams adjust staffing, run order, and schedules before delays happen. FloVision Pro gives operators and managers the data they need to improve flow and make sure teams are supported where it counts.

4. Prioritize Real-Time Alerts for High-Risk Inputs

Not every material needs nonstop tracking, but some are too important to overlook. Supplies that often hold up production—like packaging film, liners, or fast-moving ingredients—should have alerts in place to cut downtime and keep lines ready. By watching these key items closely, facilities can stop small problems from turning into bigger delays.

Choosing the Right Visibility Tools for Your Operation

The right tools depend on your operation’s size and workflow. Whether you run one line or several, your supply chain visibility system should include:

- Real-time alerts for materials that matter most

- Connection to your procurement or ERP tools

- Traceability from supplier to line to delivery

- Mobile access for floor supervisors

- The ability to grow as your operation grows

While full supply chain visibility may take time to implement, 72% of companies with end-to-end supply chain automation say they feel confident in their ability to respond quickly to supply chain disruptions (source).

Better Visibility Means Better Production

When your team has a clear view of materials and supply chain risks, planning becomes easier—and production becomes more reliable. That’s the value of supply chain visibility. It helps reduce slowdowns, limit rework, and create a smoother process from receiving to packaging.

Even small improvements—like setting alerts or combining supply data—can lead to higher output and better use of time and resources. And when materials, data, and people are all aligned, your operation can stay flexible and on track—even when conditions change.

FLOVISION NANO

Compact AI sensor to measure yield and quality at production speed.