Farming and Agriculture

Precision Agriculture

AI in food industry applications extends to farming and agriculture, where it is revolutionizing traditional practices. According to MarketsandMarkets Research, AI in agriculture is expected to grow from 1.7 billion USD in 2023 to 4.7 billion USD by 2028.

Agricultural systems use AI to analyze soil conditions, monitor crop health, and predict yields. Drones and sensors collect real-time data, which AI algorithms process to provide actionable insights. This technology enables farmers to optimize resource use, reduce environmental impact, and increase crop yields, illustrating the transformative potential of AI in agriculture.

Livestock Management

In addition to crop farming, AI in food industry practices are also enhancing livestock management. AI applications monitor animal health and behavior, enabling farmers to detect illnesses early and optimize feeding schedules. By analyzing data on livestock, AI helps improve productivity and welfare, ensuring that animals are healthy and well-cared for. This use of AI contributes to more sustainable and efficient livestock and farming practices.

AI in agriculture is expected to grow from $1.7 billion in 2023 to $4.7 billion by 2028...This technology enables farmers to optimize resource use, reduce environmental impact, and increase crop yields.

Food Production

Identifying Areas of Lost Yield and Inefficiencies

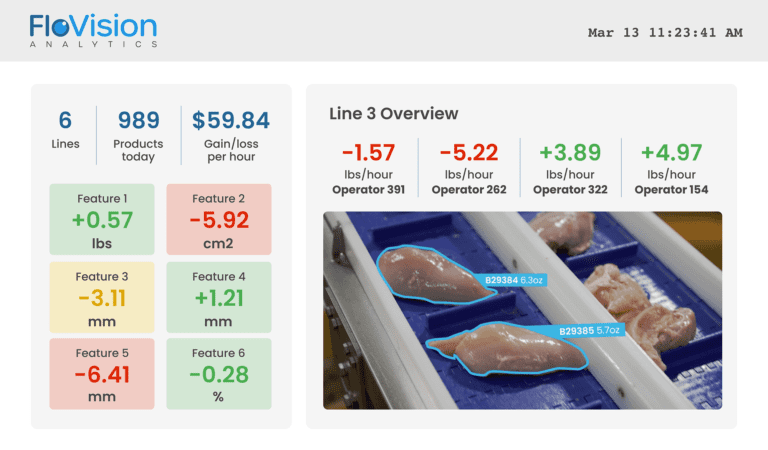

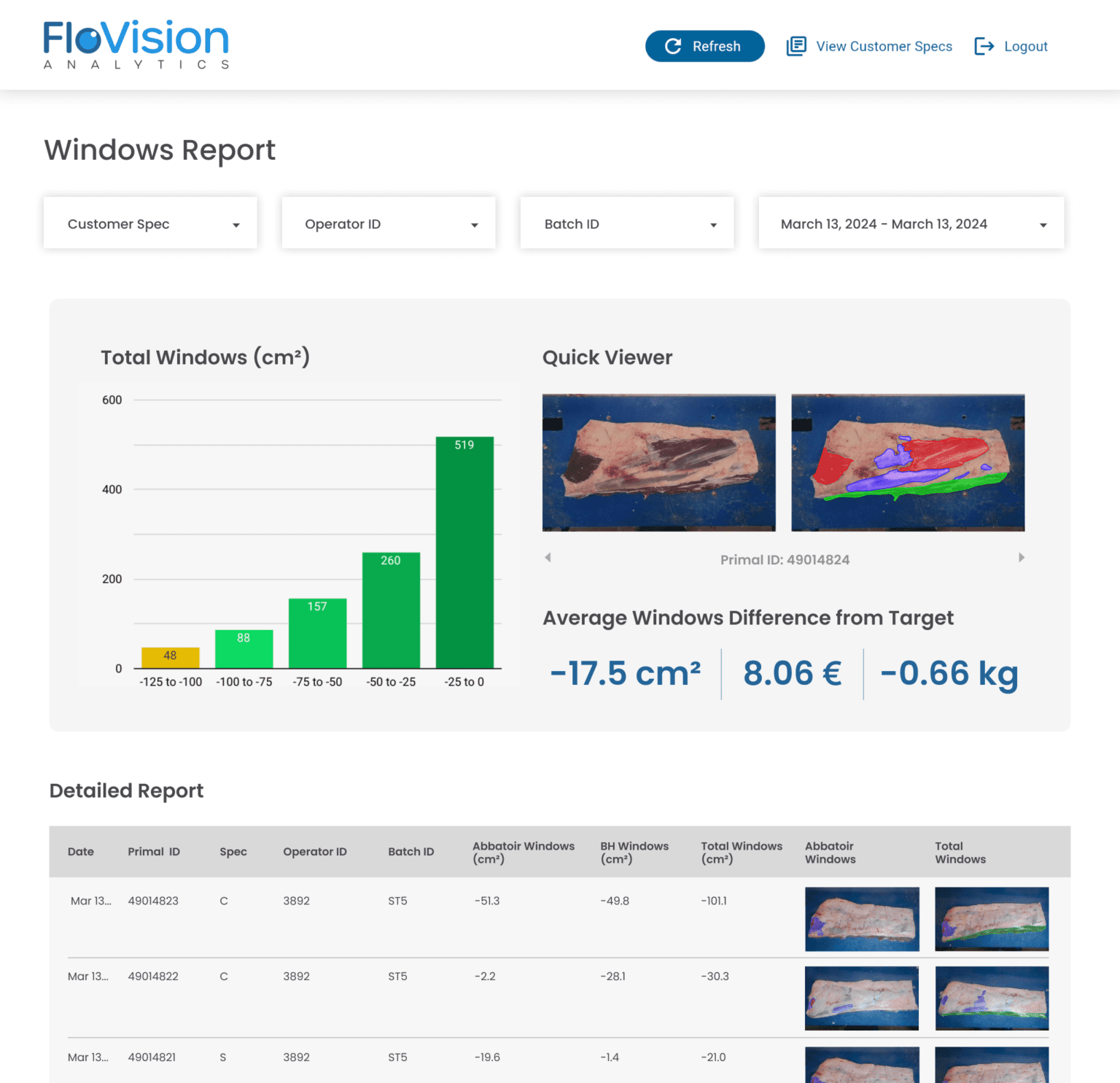

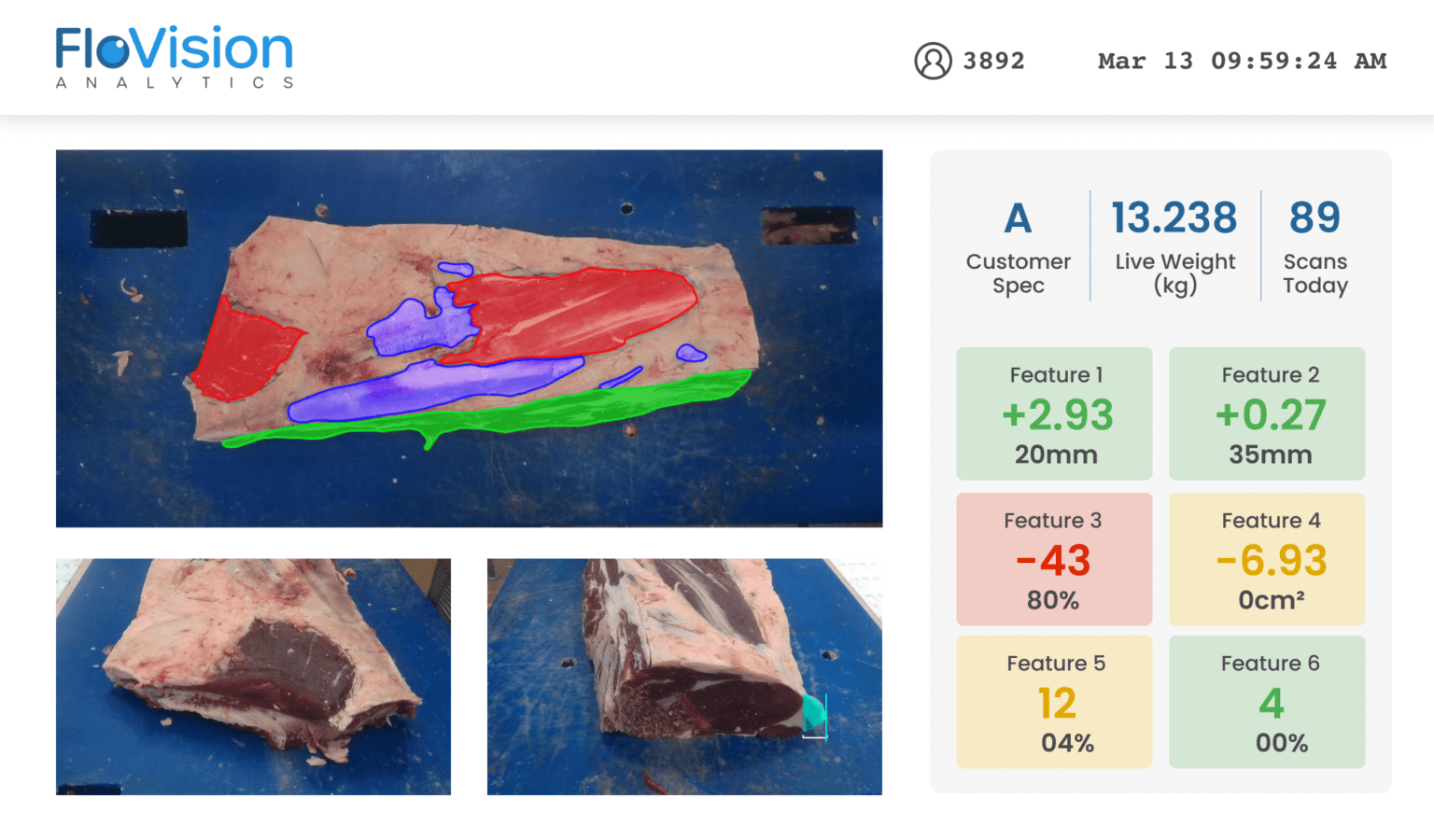

One of the most significant contributions of AI in food production processes is its ability to identify areas of lost yield and inefficiencies. AI systems like the FloVision Nano analyze data from production lines to detect inefficiencies, streamline operations, and reduce waste. For instance, by monitoring the speed and accuracy of production, AI can pinpoint where errors occur and suggest optimizations. This leads to substantial cost savings and increased yield, demonstrating the critical role of AI in food manufacturing.

Quality Check of Food Items

AI works seamlessly in food production facilities to ensure the quality and safety of food products. Automated inspection systems equipped with AI can analyze food items for defects, foreign objects, and overall quality. These systems use computer vision and machine learning to detect anomalies that might be missed by humans. This ensures consistent product quality and builds consumer trust in food safety.

Data Processing for Insights and Forecasting

AI also plays a crucial role in processing large amounts of data to generate insights and forecasts. By analyzing data from various stages of the production process, AI can predict demand, optimize supply chains, and enhance decision-making. Predictive analytics allow companies to anticipate market trends, adjust production schedules, and minimize waste. This capability underscores the importance of AI in food industry operations for achieving efficiency and profitability.

Individualized Staff Training

AI in food industry applications extends beyond production to workforce development. AI systems like FloVision Pro can assess individual employee performance and recommend personalized training programs accordingly. By monitoring worker activities and providing feedback, AI helps in continuous skill development and improvement. This individualized approach ensures that employees are well-trained, leading to better overall performance and productivity.

Scanning for Defects and Foreign Objects

Food safety is a critical concern, and AI in food industry applications address this by scanning products along the production process. Advanced imaging systems equipped with AI can detect defects and foreign objects in food products in real-time. These systems use sophisticated algorithms to analyze images and identify contaminants that could pose health risks. The ability to perform such detailed inspections ensures higher safety standards and boosts consumer confidence in food products.

Tracking Food Items through Production

AI in food industry facilities can provide product traceability far beyond human capabilities. AI-driven traceability systems track food items through every stage of the production process, from raw materials to finished products. This level of transparency is crucial for accountability and quality control, both for the processor and their customers. By leveraging AI, companies can quickly identify and address issues in the supply chain, ensuring that only the best products reach consumers.

Food Transport

Optimizing Supply Chain Logistics

AI in food industry logistics is critical for ensuring that food products reach their destinations efficiently and safely. AI algorithms optimize supply chain logistics by analyzing data on routes, weather conditions, and traffic patterns. This data allows for real-time adjustments to delivery schedules, reducing delays and minimizing food spoilage. According to McKinsey & Company, companies that introduce an AI-driven business planning platform can expect a 15% reduction in logistics costs.

Predictive Maintenance of Transport Vehicles

Another application of AI in food industry transport is predictive maintenance. AI systems monitor the performance of transport vehicles, predicting when maintenance is needed to prevent breakdowns. This proactive approach reduces downtime and ensures that food products are transported without interruptions. The integration of transport maintenance enhances reliability and efficiency, and ultimately a more seamless supply chain.

With the growing population expected to drive a 35-56% increase in food demand from 2010-2050, streamlining operations across the food industry is crucial to minimizing food waste.

Restaurants & Cafeteria

Enhancing Customer Experience

AI in food industry settings, such as restaurants and cafeterias, focuses on enhancing customer experiences. AI-driven systems provide personalized menu recommendations based on customer preferences and dietary needs. Smart ordering systems use AI to streamline the ordering process, reduce wait times, and improve service quality, leading to increased satisfaction and loyalty.

Operational Efficiency

Operational efficiency is another way AI in food industry establishments can make a significant impact. AI systems manage inventory, forecast demand, and optimize staffing levels to reduce waste and improve service. By predicting peak times and adjusting resources accordingly, AI helps restaurants operate more efficiently and profitably. This operational advantage highlights the ways AI in food industry settings can support human tasks.

Grocery Stores & Retail

Smart Inventory Management

Grocery stores benefit from AI through smart inventory management systems. AI algorithms monitor stock levels, predict consumer demand, and automate restocking processes. This ensures that shelves are always stocked with the products customers look for, reducing the risk of empty shelves or overstocking. This is reflected in consumer preference, with 69% of consumers preferring to shop with retailers that use automation technology.

Shelf Monitoring

Shelf monitoring is a critical application of artificial intelligence, leveraging AI-driven cameras and sensors to maintain the optimal customer experience. These advanced systems continuously monitor the state of shelves, alerting staff when items need restocking or when products are misplaced. This proactive approach ensures better organization and availability of products, improving the shopping experience for customers. The use of AI in shelf monitoring not only reduces the likelihood of items out of stock but also improves overall store efficiency, ensuring that shelves are always well-stocked and orderly.

The Future of AI in the Food Industry

The integration of AI in food industry practices is transforming every aspect of the food supply chain, from production and farming to transport and retail. With the growing population expected to drive a 35-56% increase in food demand from 2010-2050, streamlining operations across the industry is crucial to minimizing food waste. By identifying inefficiencies, ensuring quality, enhancing staff performance, and improving customer experiences, AI is supporting food industry leaders globally in this effort. As technology continues to evolve, the potential for AI in the industry will only grow, paving the way for a more efficient, sustainable, and consumer-friendly food ecosystem. Embracing AI in food industry operations is critical for staying competitive and meeting the demands of a rapidly changing world.FLOVISION NANO

Compact AI sensor to measure yield and quality at production speed.