Resources

Insights and news on our solutions, sustainability, and the food industry.

Beef processor increases spec accuracy by 30%

- Recovered Yield - FloVision Pro uncovered a striploin primal spec that was overtrimmed by 120% on average

- Performance Improvement - Butchers used laser guides to achieve consistent spec trimming

- Bottom Line - The processor recovered $68,400 yearly by correcting this error

How to Detect Foreign Objects and Defects in Poultry Processing at Line Speed

At 175 birds per minute, human inspectors have just 0.34 seconds to catch every defect—here’s why that’s physically impossible and what leading poultry processors are doing instead.

3 Steps to a 1.5% Meat Processing Yield Improvement

A consistent 1–1.5% meat processing yield improvement can be the difference between a tight quarter and a strong one. In plants with slim margins, small gains add up quickly.

Improve Quality Control in the Food Industry and Strengthen FSQA Compliance

In modern food production, quality control in the food industry is the indicator of safe, consistent, high-quality output. As supply chains scale and consumer expectations rise, teams need systems that deliver transparency, traceability, and speed from raw materials to shelf.

This blog outlines Food Safety and Quality Assurance (FSQA) fundamentals, why consistency is hard, and how AI elevates quality control beyond manual visual inspection.

Why Supply Chain Visibility Matters in Today’s Food Production

Keeping food production lines running smoothly is more challenging than ever. Delayed materials, unreliable suppliers, and tight delivery windows can throw off even the best schedules. What starts as a small issue—like packaging arriving late—can quickly lead to waste, rework, or extra labor. In fact, around 30% of all food produced for humans is wasted or lost along the supply chain.

How Poultry Production Varies Across the Globe

Poultry production looks different in every corner of the world, shaped by culture, technology, and regulation. From high-tech plants in North America to small-scale operations in Asia and Africa, regional practices impact everything from yield to food safety.

How Food Processors Can Increase Throughput and Maximize Efficiency

For food processors, throughput is profit. The ability to process more heads per hour, pounds per minute, or cuts per second without compromising quality directly impacts profitability. However, bottlenecks, human error, machine downtime, and quality control issues can slow down production, leading to higher costs and lower yield.

How to Safeguard Against Food Production Staffing Challenges

In today’s fast-paced food production industry, staffing challenges are not just an inconvenience—they can directly impact productivity, quality, and safety. With labor shortages, high turnover rates, and ever-increasing demands on production lines, it’s essential for managers to implement robust strategies that ensure smooth operations and effective production staffing.

Methods of Beef Production Across the Globe

Beef has long been a cornerstone of diets around the world, and each region has developed its own approach to raising, processing, and distributing it. Explore how beef production differs around the world and how technological advances are helping the industry meet global and regional challenges.

Critical Human Errors in the Food Production Industry

The food production industry is a complex network of processes where even a minor error could lead to substantial repercussions. Every step requires precision to ensuring consistent product quality and maintain efficiency and safety. Despite rigorous protocols, human errors continue to pose challenges that impact profitability, safety, and reputation – and according to the Annals of Operations Research, human error accounts for 10.9% of all food waste. Explore common human errors in the food industry, their impact, and strategies to minimize them below.

Revolutionizing Sustainable Food Production with Food Technology and Quality Control

In today’s world, sustainable food production has become a pressing necessity. As global populations grow, the demand for food increases, putting immense pressure on our food systems. By leveraging food technology and quality control like AI and computer vision, the food industry can reduce environmental impact and ensure a more efficient and sustainable future.

5 Proven Strategies to Streamline Poultry Processing Lines

In 2020, poultry production represented nearly 40% of global meat production. Efficient production is critical to ensuring profitability, maintaining product quality, and meeting the demands in the competitive poultry market. Streamlined processes can significantly enhance yield, reduce waste, and improve overall operational performance. Poultry processors can use proven strategies like automatic quality scans, trimming standardized operating procedures, strategic production timing, by-product allocation, and visual management to improve efficiency and increase their bottom line.

AI in Food Industry Operations: Transforming Farming, Production, and Retail

Artificial Intelligence (AI) is revolutionizing operations across various industries, and the food industry is using it to drive significant transformation. From optimizing production processes to enhancing consumer experiences, AI in food industry applications is revolutionizing how food is produced, processed, transported, and consumed.

Cutting Losses: Strategies for Reducing Yield Loss in Pork Processing

In the highly competitive pork processing industry, yield—the percentage of product that is usable from raw material—is a critical metric that directly impacts profitability. Pork processors often face challenges that can cause significant yield loss, affecting their bottom line.

Maximizing Yield: The Role of AI in Food Quality Control

The need for effective food quality control measures in the food processing industry is more pressing than ever. Challenges like imperfect processing, overproduction, and various quality issues lead to significant food waste, causing both economic losses and environmental harm.

How AI is Transforming the Meat Industry

Artificial Intelligence has massive implications on cost savings, operations, and decision-making for fast-paced, manual processes like meat production.

How American Beef Processors Maximize Throughput

Meat processing methods vary across different regions, shaping how butchers approach their tasks and the speed and accuracy with which the product is processed.

Delicacy or Disgusting? Beef’s Most Controversial Cut

Rump cap, also known as picanha, is a popular cut of beef in Brazil, and it is highly valued for its tenderness and rich flavor.

How Does American Meat Processing Differ from the Rest of the World?

American meat processing facilities prioritize throughput or the volume of meat that can be processed in a given amount of time.

Grass-Fed Beef: Health Benefits, Sustainability, and Animal Welfare

Grass-fed beef has been gaining popularity in recent years due to its perceived health benefits and environmental sustainability.

Grain-Finished vs. Grain-Fed Cattle

Grain-finished cattle are fed a grain-based diet (such as corn or soybeans) for a shorter period, usually a few months, towards the end of their lives in order to fatten them up and improve the flavor and tenderness of their meat.

Rump Cap in Brazil: Picanha

Rump cap, also known as picanha, is a popular cut of beef in Brazil, and it is highly valued for its tenderness and rich flavor.

Where Does Ofall Have the Most Value?

In some cuisines, offal beef is a more affordable source of protein compared to other cuts of meat.

Is Your Third Party Equipment Food Safety Compliant? Cleaning vs. Sanitizing

In food and beverage processing, cleaning and sanitizing are different processes that prevent product contamination and employee safety.

Global Beef Cuts: Rump

In America, rump is commonly known as the round. It is a muscular cut of beef that comes from the rear of the cow. It’s a relatively lean cut and can be tougher than other cuts, but can still be tender if it’s cooked correctly.

Where Does Brisket Have the Most Value?

In America, brisket is considered a premium, high-value cut of meat. It is a large cut of meat that can feed a crowd, and the popular slow-cooking process used in barbecue allows the brisket to become tender and flavorful.

Is Your Third Party Equipment Food Safety Compliant? Clean In Place vs. Clean Out of Place

In meat production facilities, equipment and instruments can either be Clean In Place (CIP) or Clean Out of Place (COP).

Is Your Third Party Equipment Food Safety Compliant? Harborage Points

Harborage points are defined as any place within the equipment that creates an environment where bacteria can grow.

Is Your Third Party Equipment Food Safety Compliant? Hygienic Design

Hygienic design in meat processing equipment is not only required for compliance with food regulatory agencies, but also improves production safety, product quality, and time associated with cleaning.

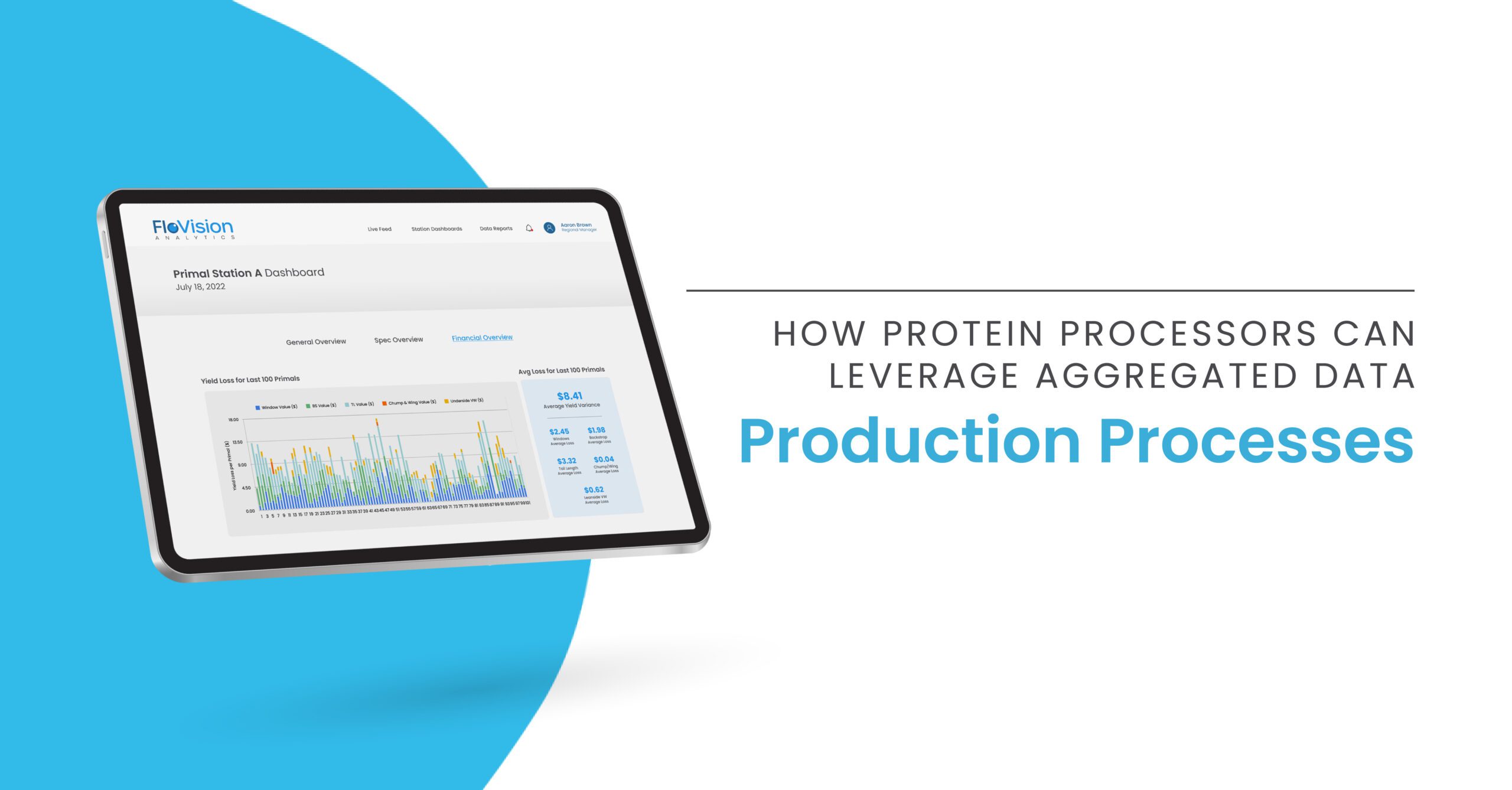

How Protein Processors Can Leverage Aggregated Data: Production Processes

Many of the processes in meat processing require optimization to get the most valuable and highest quality product, which can be achieved with aggregated data.

How Protein Processors Can Leverage Aggregated Data: Trimming Performance

Aggregated data can help protein processors get performance metrics on their production, which can be difficult to quantify otherwise.

How Protein Processors Can Leverage Aggregated Data: Meat Quality

For protein processors, aggregated data can be particularly useful in understanding trends in an industry in which every product is unique. Collecting this aggregated data on meat quality, trimming performance, and production processes helps meat processors to recover yield and produce higher quality products.

Is Your Third-Party Equipment Food Safety Compliant? Contact Surfaces

When it comes to contact surfaces, meat processors must ensure that any third-party equipment and technology hardware is food safety compliant.

How a Connected, Automated System Improves Protein Processing Yield

In the protein processing industry, yield is everything. That’s why more and more processors are turning to connected, automated systems to help them improve their production yields.

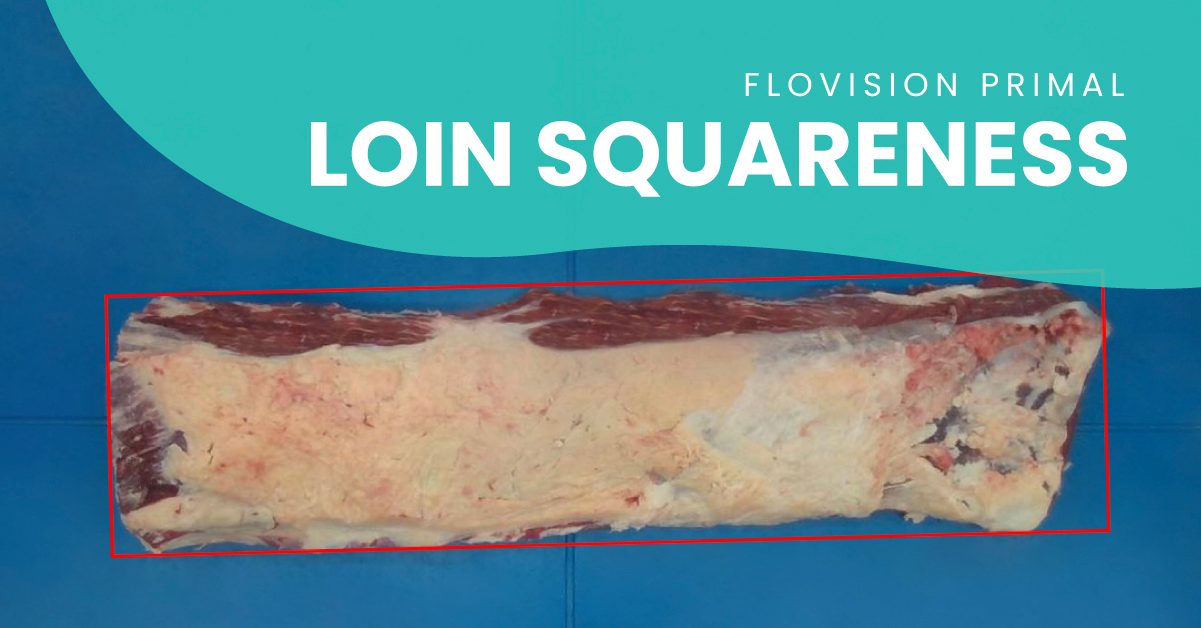

FloVision Primal: Loin Squareness

Loin squareness is a smaller measurement in the primal butchering method, but at FloVision Solutions, we’re invested in the details. Our solution measures loin squareness on primal lines in real-time to confirm butchers are positioning primals appropriately for trimming and to ensure backstraps, chump angle, and wing angle are trimmed to customer spec.

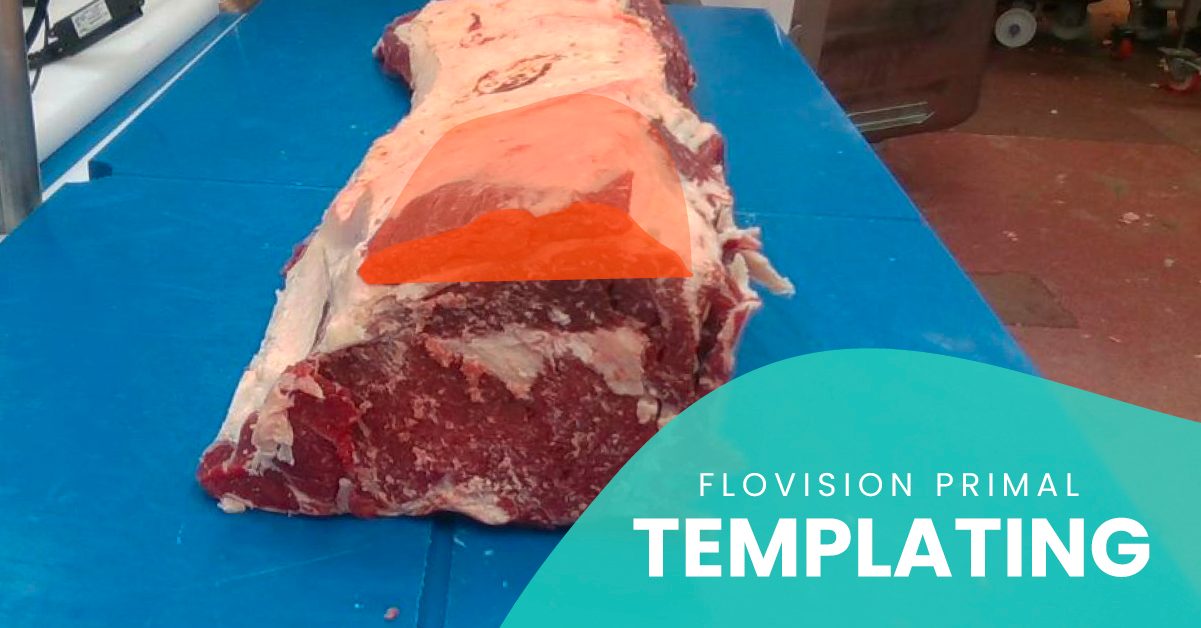

FloVision Primal: Templating

Templating takes valuable time from the primal butchering process. FloVision Solutions provides automated, precise primal measurements that save meat processors time, yield, and revenue.

FloVision Primal: Chump & Wing Angle

Improper cuts to both chump and wing angle can result in lost sirloin primal value. Depending on customer spec, chump angles should remain natural around 15°, or squared at 4°, and wing angles should be squared at 0°. Variance from these angles results in yield lost to primals of lower value or trimmings sent to visual lean lines.

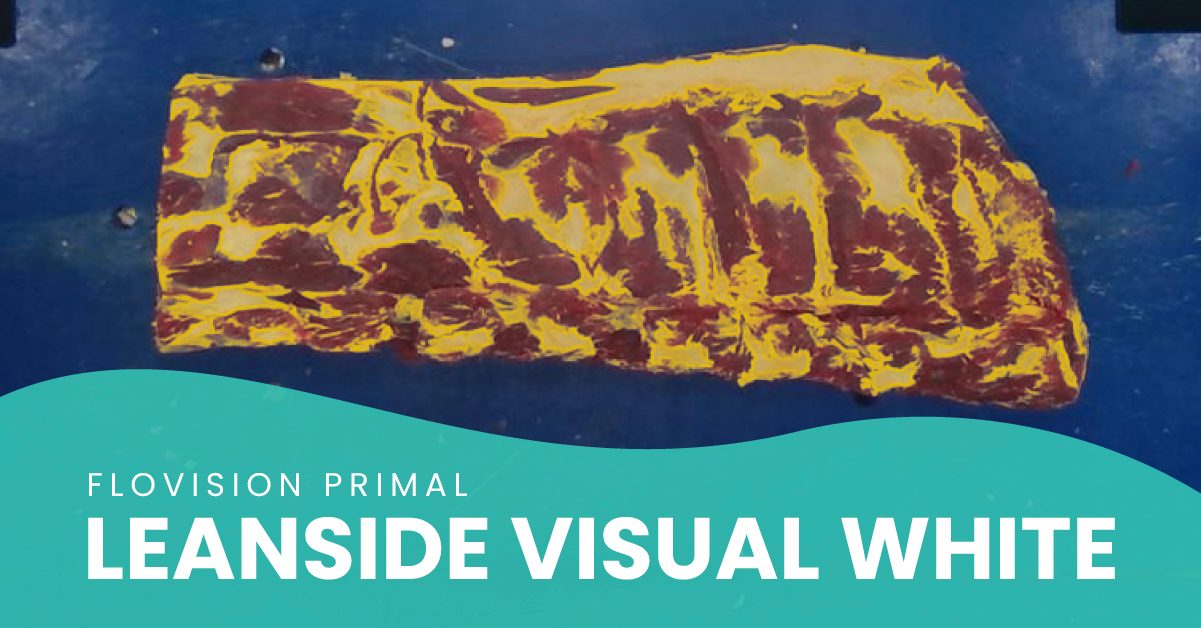

FloVision Primal: Leanside Visual White

Maximizing the fat on the lean side of a primal is a key point of profit for industrial beef processors. Fat and lean still attached to the bone after deboning is lost yield, sent to a rendering plant; when kept attached to the primal, it increases primal weight and value.

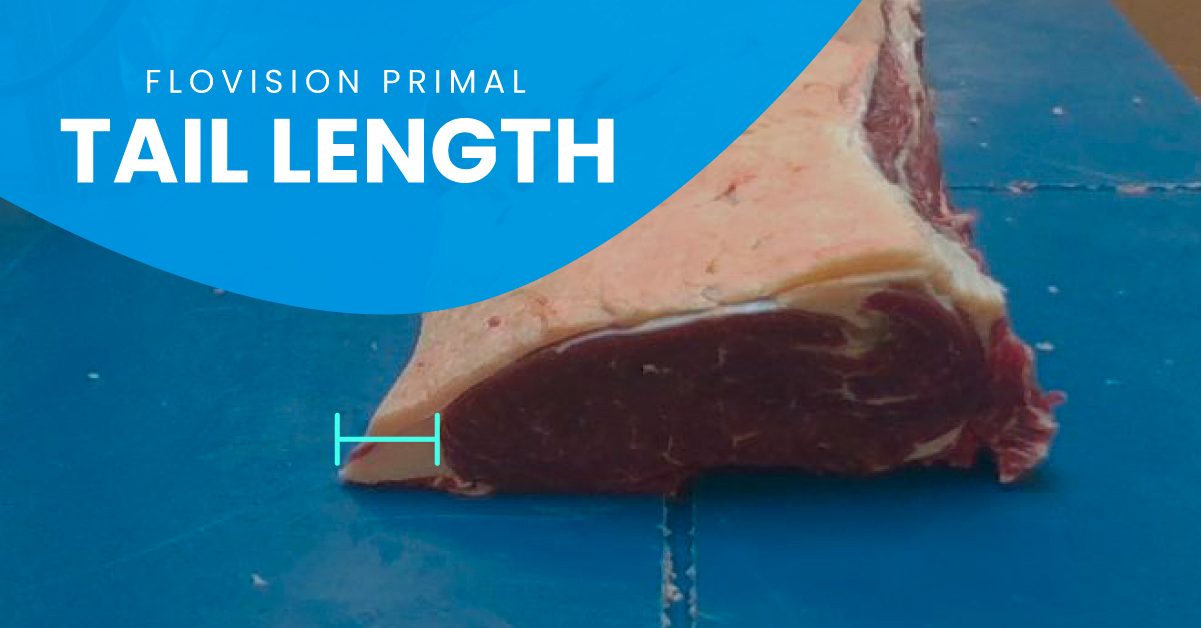

FloVision Primal: Tail Length

Meat processors are losing yield on tail length trimming – approximately $3.60 per head. With variability in both spec and untrimmed tail length, accurate cuts can be difficult to perform in real time and improper cuts can have a significant impact on the final value of a primal.

FloVision Primal: Backstrap

Primal backstraps are tough and important to remove to ensure customer quality; removal spec is typically set to a maximum width, e.g. 25mm. Trimming inconsistencies that fall outside of the spec result in significant loss of yield and profit on each primal.

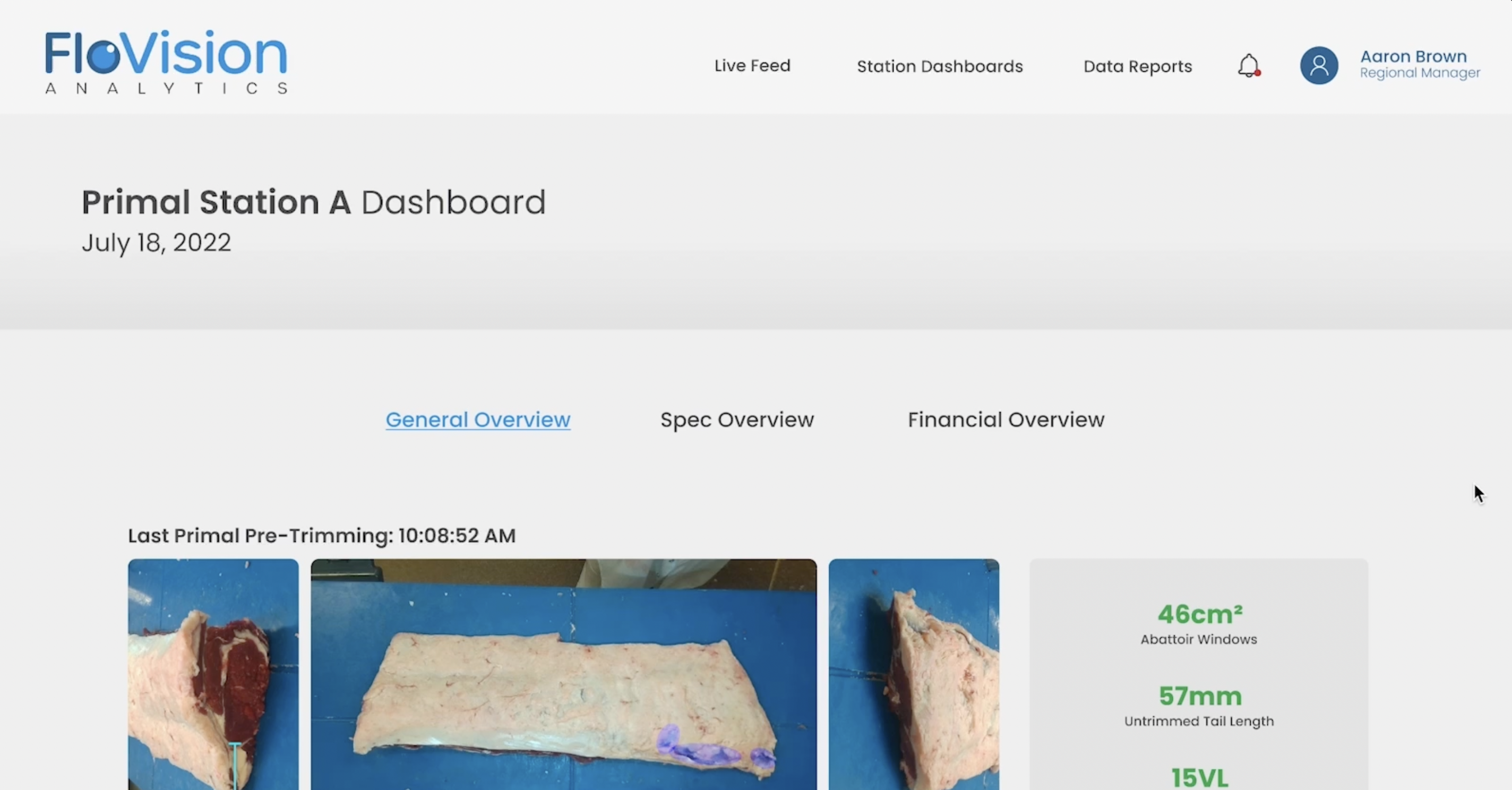

FloVision Primal: Windows

Meat processors lose the most primal yield on excess fat removal (“windows”). On average, each head loses $4.54 from fat pulled off during hide removal or improper primal cuts on the trimming table.

FloVision Primal: How Meat Processors Are Leveraging Technology to Recover Millions Annually

A quick breakdown of the technology that’s helping industrial meat processors recover millions in profit from lost primal yield.

How to Leverage Body Fat and Lean Value Shifts

With supply chain shortages and shifts in consumer demand beginning in 2020, the meat processing industry has seen a dramatic increase in value for an unexpected product – body fat. Since 2019, fat has stayed at a consistent $0.71 [€0.62] per kilogram on average; in April 2021, this number began to steadily rise, with the most recent reporting indicating a nearly 250% increase at $1.68/kg [€1.48/kg].

FREE GUIDE

5 Proven Ways to Maximize Striploin Primal Yield

Discover the features of striploin primals that lose the most value and five ways to measurably improve yield on these features.